- •Topic 1: Introduction. Nanocrystalline materials (4:00)

- •Topic 2 obtaining nanopowders (4:00)

- •In this case, unlike the titanium alloys are widely used in medicine, pure titanium has a complete biocompatibility with bone tissue.

- •Topic 4: Controlled crystallization of amorphous materials (4:00)

- •Topic 5 Compaction of ultrafine powders (4:00)

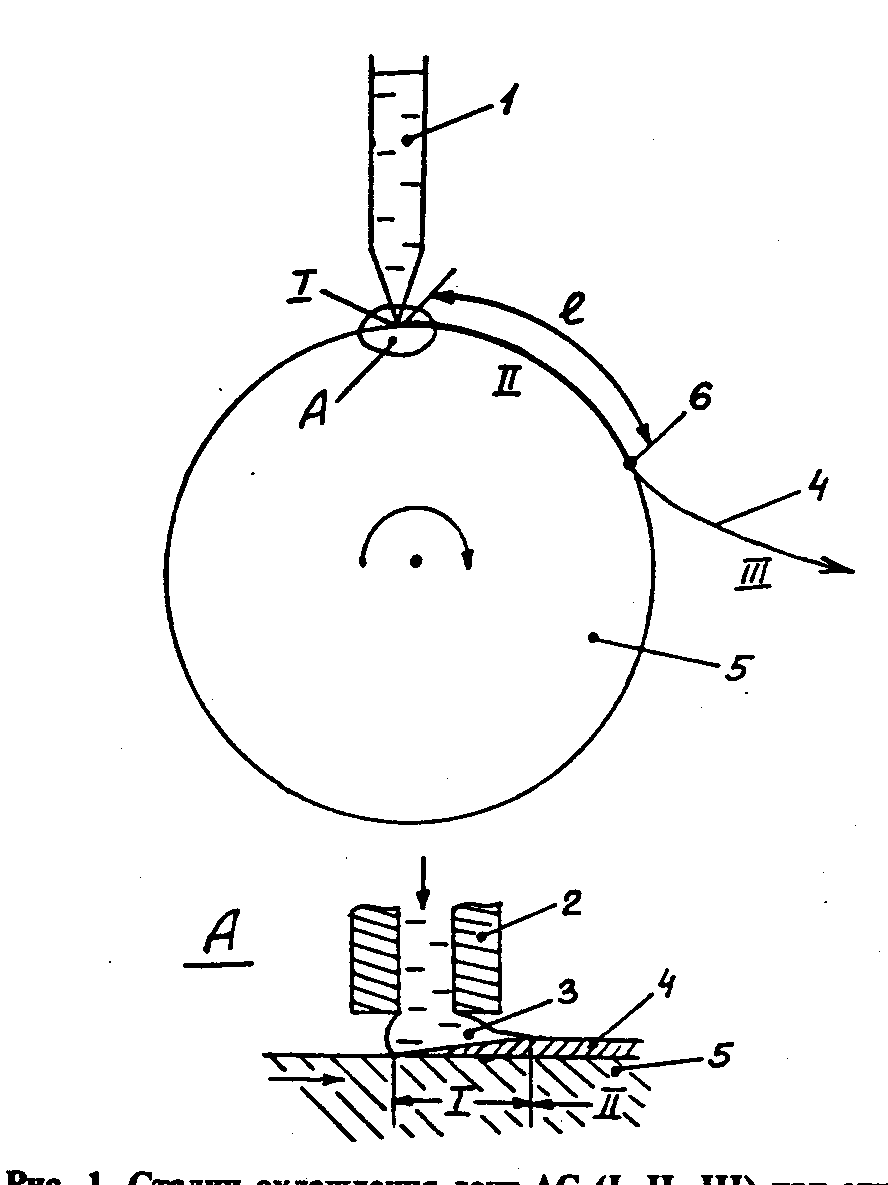

- •Figure 1.1 - Scheme of production of bulk nanomaterials by evaporation, condensation and compaction

- •Topic 6: Severe plastic deformation of materials with conventional grain size (4:00)

- •Topic 7 In micro-and nano-electronics (4:00)

- •Topic 8 Commercial prospects of nanomaterials (2:00)

- •In recent years more and more attention is drawn to multistage filled nanotubes with an outer diameter of 2 ... 70 nm and lengths up to 60 microns.

Topic 8 Commercial prospects of nanomaterials (2:00)

Plan of the lecture

1. Nanowires and nanofibers.

2. Carbon nanotubes.

3. Commercial prospects of nanomaterials.

Nanowires and nanofibers. Nanowires, metal nanowires for electronic circuits, as well as nanowires from point of nanoparticles ("flies"), grow by condensation from the vapor phase on stepped substrates. Requires that the surface energy of the substrate material surface energy exceeds the absorbate. So, to get the copper wires required substrate of molybdenum. On tungsten, which has a higher surface energy, forming a chain of nano-"flies". The essence of the process is that the steam particles deposited on the plane "step" under the influence of surface forces on a plane diffuse step in her corner, where there are forces of the two planes. The process produces nanowires, in the form of "bars" with a diameter of about 1 nm, and in the form of a "strip" of the same thickness with a width of 20 ... 60 nm. To obtain nanowires made of semiconductors such as InGaAs alloy, etc., use the methods of selective epitaxy. The wire is formed to "comb" the substrate between the two epitaxial layers.

Nanowires from silicon and germanium. Nanofibers (nanowires) silicon adhesive coating of SiO 2 and germanium nanowires has attracted much recent attention as a material for electronic nanodevices. To receive them have been tried various methods, including photolithography, etching equipment, etc. The most promising was the method of laser irradiation of mixtures of Si + Si O2, Si + Fe2O3, Ge + SiO2, Ge + GeO2 well-known scheme PZHT (vapor - liquid - solid).

Carbon nanotubes. Carbon nanotubes as hollow and filled with either metal or carbides or oxides obtained in several ways: by pyrolysis of hydrocarbons in the presence of a metal catalyst at 700 ... 10000 C in the arc discharge at the end of the graphite cathode, electrolysis of salt halogens between graphite electrodes.

In recent years more and more attention is drawn to multistage filled nanotubes with an outer diameter of 2 ... 70 nm and lengths up to 60 microns.

Tubes filled with iron, nickel, cobalt and samarium-cobalt intermetallics SmhSou type used in magnetic ink and toner for xerography. Tubes filled with refractory metal carbide (TaC NbS, MoC) at temperatures below 10 K can be used as nanosverhprovodniki.

Commercial prospects of nanomaterials

Development of nanomaterials in recent years, surely goes to the industrial level. Some countries and associations (U.S., Japan, NATO, etc.) are investing hundreds of millions of dollars into the development of methods of synthesis, studies of the properties, nanomaterials, manufacturing equipment and structures using nanomaterials.

Already in the late 80s of the twentieth century the United States and Japan spends on research in the field of nanomaterials of 110 ... $ 120 million. Only in the U.S. more than three dozen companies are on a different level on their production. Many nanomaterials are already available on the market. They are now widely used in microelectronics, contributing to the further miniaturization of electronic devices, protective systems absorb HF and X-rays, as catalysts. In nuclear power fuel rods are made of pills UDP UO2, in fusion physics from UDP produce beryllium target for laser fusion. Metal nanopowders added to motor oils to restore the rubbing surfaces. Nanomaterials are used as structural materials and heavy-duty water-resistant coatings. Film nanomaterials flat and complex form of soft magnetic alloys are used for video head VCR, significantly exceeding the service properties of traditional materials. Received plasma-way UDP metal carbide inclusions are used as ground and polished material at "finishing" semiconductors and dielectrics.

In medicine, UDP is used to protect personnel from the X-ray equipment (gloves, aprons, rubber, etc. With UDP lead-filled four times lighter than normal), and for drug absorption and quick action, used in extreme conditions injured in accidents, fighting, etc.).

In the military UDP used as radar absorbing coatings aircraft invisible "Stealth", in new kinds of explosive weapons. In "graphite bomb" uses carbon nanofibers, disabling power of the enemy. Tubular carbon nanofibers, fullerenes are promising for reinforcing composite "superbroni" for tanks and body armor.

Promising properties of nanomaterials is that you can safely say, from 90 years of the twentieth century, scientific and technological progress was determined by nanomaterials and nanotechnology.

The commercial market have long gone out not only metal, but also non-metallic nanomaterials such as silica and iron and aluminum oxides, titanium, antimony, etc. go to the market. Have become available, some carbide with a particle size of 20 ... 200 nm. Rapidly evolving market itself nanomaterials. Thus, only in the U.S. for five years from 1996 to 2000. market size of nanomaterials has grown from 42 to 154 million dollars a year. [1] In this case, the average annual market growth of nanomaterials was almost 30%, including 24.2% of nanoparticles and nano-43.1%.

In large countries, formed long-term programs of development and practical use of nanomaterials. As the main concern at the practical development of technologies for the production of nanomaterials in large enough quantities and competitive in the goods markets.

Recommended Reading

New materials / VN Antsiferov, FF Bezdudny, LN Belyanchikov and others, ed. YS Karabasova, Ministry of Education of the Russian Federation. - Moscow: MISA, 2002. - 736 p.

New substances, materials and products made of them as objects of inventions: Directory / VI Blinnikov etc. - Moscow, Metallurgy, 1991. - 262 p.

Rzhevskaya SV Materials science. - M. Bauman, 2000. - 280.

Kulikov V.Yu. Textbook for the course "New Materials", KSTU, 2006.

Morokhov ID, Cowards DD, Lapovok VI Physical phenomena in ultra environments. - Moscow: Nauka, 1984.

Gusev AI Nanocrystalline materials: preparation methods and properties. - Ekaterinburg, 1998.

Control tasks for independent work of the student (theme 8) [1, 2, 3, 7]

1. Compacting powders.

2. Torsion under high pressure.

3. Grain equal channel pressing.

4. Exclusive features of nanostructures.

5. Carbon nanotubes.

4.Thematic plan of independent work of a student with a teacher

-

Name of topic SRMP

purpose of the lesson

The form of the

зааниданСодержия е

Recommended Reading

1

2

3

4

5

Topic 1. Nanocrystalline materials.

More knowledge on the subject

interview

Determine the features of the structure and properties of nanocrystalline materials

[1, 2, 3]

Theme 2. Nanopowders.

More knowledge on the subject

calculation

Calculate the optimal process conditions nanopowders.

[1, 3]

Theme 3. properties of nanopowders.

More knowledge on the subject

interview

Evaluate the properties of nanopowders depending on how they are making

[1, 3]

Theme 4. Controlled crystallization of amorphous materials

More knowledge on the subject

interview

Consider the kinetics and thermodynamics of crystallization of amorphous metal alloys

[1, 3]

Theme 5. Compaction of ultrafine powders.

More knowledge on the subject

calculation

Calculate the optimal process conditions compaction of ultrafine powders

[1, 3]

Theme 6. Severe plastic deformation of materials with conventional grain size

More knowledge on the subject

calculation

Calculate the optimal process conditions for severe plastic deformation

[1, 3]

Theme 7. Material micro-and nano-electronics.

More knowledge on the subject

interview

Select optimum materials for a specific purpose in micro-and nanoelectronics.

[1]

Theme 8. Commercial prospects of nanomaterials.

More knowledge on the subject

interview

Consider ways to increase the use of nanomaterials

[1, 2, 3]

7 Materials for control of knowledge during a landmark master control and final testing

7.1 Subject of written work on discipline

Subject abstracts

1. Nanomaterials.

2. Polucheknie nanopowders.

3. Model nanostructures.

4. Actual problems of technology for semiconductors.

5. Devices based on silicon nonplanar.

6. Single-crystal growth

7. Epitaxial structure.

8. Fullerenes - the materials of the future.

9. Metal composite materials.

10. Ceramic carbon materials.

11. Carbon-carbon composites.

12. Methods for producing composite materials.

13. Powder materials.

14. Superconducting nanomaterials.

15. Methods polucheiya nanopowders.

16. Nanomaterials for magnetic recording.

17. Alloys increased reliability.

18. Structural Nanomaterials for nuclear power.

19. Nnostrukturnye shape memory alloys.

20. Amorphous metal alloys.

21. Multicomponent nanostructured films.

22. Functional coatings.

23. New soft magnetic nanomaterials.

24. New-magnetic nanomaterials.

25. Ferrites.

7.2 Questions for self-control

1. What is meant by ultrafine materials or nanomaterials?

2. How many times will give an increase in strength reduction of the metal grain size from 10 microns to 10 nanometers?

3. How has the development of nanomaterials in the XX century?

4. What is the current trend in the development of nanomaterials?

5. What determines the relevance of Manufacture of ultrafine or nano-materials?

6. What are the methods for the preparation of ultrafine materials?

7. What are the chemical methods of nanomaterials?

8. What are the physical methods of nanomaterials?

9. What are the mechanical methods of nanomaterials?

10. What are the biological methods of nanomaterials?

11. Which there are currently three areas receiving bulk nanostructured materials?

12. What is the method of controlled crystallization of amorphous materials?

13. What is the method of compaction of ultrafine powders?

14. What is the method of severe plastic deformation of materials with conventional grain size?

15. What is a carbon nanotube? What are their features?

16. What is the promise of the properties of nanomaterials?

17. As used in medicine nanomaterily?

18. As in the military uses nanomaterials?

19. How are nanomaterials in the nuclear industry?

20. Where are film nanomaterials?

21. Where in the modern science and technology uses solid materials?

22. What are the characteristic features of the present stage of development of electronic technology?

23. List the most important of semiconductor material?

24. What material is a modern solid-state electronics is the primary?

25. What is the main trend in the development of technology for single crystals?

26. Which method is the most versatile for growing single crystals of large diameter?

27. In recent years, used to control the heat and mass transfer processes in a large mass of molten?

28. What processes are used to make the grown single crystal of various electrical parameters?

29. What are the requirements for optical materials used in infrared devices?

30. What are the main properties have single crystal germanium crystal ¬?

31. What is the essence of the method of directional solidification?

32. What are two possible ways for razraschivaniya mono ¬ crystal in the radial direction?

33. What is the condition of maintaining single crystal ¬ nomic growth?

34. What are the modifications of carbon?

35. What is a carbine?

36. What method is used for the synthesis of endohedral fullerenes?

37. What are the use of fullerenes?

38. What is the state of fullerenes are of practical interest?

39. Brief information about the ion-plasma coatings

40. What are nanoamorfnye metal materials (nanostekla)?

41. What methods are used for the production of bulk amorphous metal alloys?

42. What serious difficulties for compacting methods of amorphous metal alloys?

43. What are the patterns of visco-plastic flow of amorphous metal alloys?

44. What are the mechanisms of formation and structural states nanoamorfnyh solids?

45. What kinetics seal compact nanoparticles of amorphous metal alloys?

46. What is the first stage of compression compact particle growth - the near-contact particle necks?

47. What is essential to obtain a massive amorphous metal alloy?

48. What is the equation of the relative density of the compact?

49. What does the decimal prefix "nano"?

50. What are the causes of size effects in nano-scale objects?

7.3 Examination tickets

1. Determine the development of new materials industries such as (select them) ...

a) Industry

b) rocket

c) Medicine

g) Service

d) construction

2. To technologies that can radically change the whole structure of production are (choose the right) ...

a) Information Technology

b) the technology of new materials

c) the technology of mineral processing

d) Biotechnology

e) Genetic Engineering

3. According to expert estimates in the next 20 years will be replaced by a fundamentally new ... percent of the materials.

a) 10

b) 30

a) 50

g) 70

d) 90

4. High level of development to obtain materials (select them) ...

a) ceramic

b) for microelectronics

c) composite

d) polymer

e) superhard

5. For the development of technology of high temperature composite materials needed by (choose the right) ...

a) carbon fiber

b) diamond crystals

c) the carbon matrix

d) carbide-carbon matrices

e) intermetallics

6. Superalloys can not be used in the engines of current and future missiles, as their ...

a) The operating temperature is below 40 000 C

b) the strength of less than 100 MPa

c) the density of more than 2 g/cm3

d) Production of high-cost

d) production is not possible in an industrial environment

7. In aviation gas turbine engines and need materials with strengths up to 250 MPa and a coefficient of thermal expansion ...

a) a unit

b) Unit

a) 0.5

g) was close to zero

e) does not depend on temperature

8. Nanotubes produced by arc discharge in helium, are a new form ...

a) fiber

b) an inert gas

c) ionized plasma

d) condensed carbon

e) anisotropic iron

9. Diameter multiwall carbon nanotubes is of the order of tens of nanometers and a length of up to several ...

a) nm

b) micron

c) millimeters

d) cm

d) kilometers

10. Ensuring the share of gas turbine engines at 0.05 ... 0.08 kg / kg is achieved only by applying (select them) ...

a) materials based on ceramics

b) composites with a polymer matrix,

c) composite metal matrix

d) intermetallics

e) high-temperature alloys with single-crystal structure

11. "Smart" materials used in the manufacture (choose the right) ...

a) cladding hulls of ships

b) samouprochnyayuschihsya helicopter blades

c) sound-absorbing industrial designs

d) "artificial lung"

e) structures with adaptive variable properties

12. Laying the foundations of directional solidification process catalyzed synthesis allowed range ...

a) composite crystals

b) polymer

c) building glass-crystalline materials

d) carbon nanotubes

d) amorphous liquid crystals

13. Glass-crystalline materials are characterized by (choose the right) ...

a) high chemical resistance

b) high resistance to abrasion impact

c) decorative properties

d) optical properties

e) low wear resistance

14. Materials for replacement demand (select them) ...

a) bioinert

b) the stability properties

c) the durability of the

d) a high level of physical and mechanical properties

e) bioactivity

15. Superconducting material is used in the ...

a) medical scanners

b) separators for fine cleaning

c) sound-absorbing industrial designs

d) fixtures and fittings Industrial Physics

e) energy storage

16. Materials with biological activity and ability to coalesce with the living bone tissue, called ...

17. Technologies to bridge the gulf between the industry and the environment - is ...

a) glass-crystalline technology

b) Biotechnology

a) Information Technology

d) technology for optical single crystals

d) membrane technology

18. For efficient separation of liquid and gaseous media, allocation of valuable products from wastewater separation of ions in batteries are ...

a) Liquid Crystals

b) glass-crystalline materials

c) membrane

d) highly conductive conductors based on Cu-Nb

e) biositally

19. One of the limiting factors in the rapid spread of new materials is their ...

a) the highest price

b) is not widely used

c) does not match environment

d) making the problematic

d) low mechanical properties

20. Self-propagating high-temperature synthesis contributes ...

a) reduce the price of new materials

b) improve the physical and mechanical properties

c) extensive use of new materials

g) environmental performance of the resulting materials

e) superconductivity materials

21. Self-propagating high-temperature synthesis contributes to (choose the right) ...

a) high-performance technology

b) the use of the chemical energy of the reactants

c) higher prices for the production of new materials

d) Facilitation of high temperature equipment

d) increase the physical and mechanical properties of materials

22. Very attractive use in medicine of NiTi implants, as they ...

a) have an extremely low price

b) have a shape memory

c) have the properties samorazgruzheniya at high loads

d) have high strength

d) can play any organ of the human body

23. In the XXI century, the rapid growth is expected (choose the right) ...

a) Semiconductor

b) Nanotechnology

c) optical fiber technology

d) micromachines

e) The construction industry

24. One of the most important areas that determine the development of all sectors of industry, construction, medicine and services - is ... materials.

25. The main types used in solid-state X-ray detection systems (x) and γ-radiation are (choose the right) ...

a) op ¬ cal sensors

b) semiconductor sensor

c) membrane

d) scintillators

e) gas ionizers

26. Op ¬ cal sensors, trans ¬ form a ionizing radiation in the ... signal.

27. Semiconductor sensors convert light into ... a signal.

28. Semiconductor detectors and x-γ-radiation of modern technologies provide significant quantities of only ...

a) iron and carbon

b) silicon and germanium

c) lead and sodium

d) tellurium and iodine

e) barium and osmium

29. The disadvantage is ... TlBr

a) high water absorption

b) lack ¬ condition of phase transitions between room temperature and Tm

c) high melting point

d) low hardness

d) a narrow band gap

30. Define the sequence of cleaning thallium halide.

a) treating TlBr ¬ vacuum distillation

b) fusion salts TlBr

c) the deposition of salt TlBr from nitric acid solutions

d) separation from fused polycrystalline ¬ ka top and holding directional solidification

d) drying the salt TlBr

31. Change ¬ tion of the resistivity along the slit ¬ ka TlBr in directional solidification is due ...

a) lack of vacuum treatment

b) the gas porosity in the upper part

c) ionization ingot surface

d) the presence of impurities in the dielectric directional solidification

d) an increase in the electrically active impurities are pushed aside at the end of the ingot

32. In the initial stages of purification TlBr magnitude resistivity limit the electrically active impurity ¬ WIDE ... distribution coefficient of unity.

63. As a basis for uncooled semiconductor ¬ O detectors can be used such substance wa ¬ as (select them) ...

a) CdTe

b) HgI2

a) GaAs

g) TlBr

e) diamond

34. When cooled sensors based on TlBr to ..., accom ¬ tance increases by 1-1.5 order.

a) +200 C

b) 00 C

a) -10 ° C

g) -500 C

d) -1000 C

35. Nanoamorfnye metallic materials are one of the classes ... materials.

36. Nanoamorfnye solids are ... amorphous nanoparticles.

37. For the production of bulk amorphous metal alloys used techniques such as (select them) ...

a) warm compaction

b) extruding

a) cold in mold

g) dynamic compaction

e) Powder Metallurgy

38. In applying the method of heat pressing compacting powders is carried out in the temperature range near the temperature ...

a) liquidus

b) the solidus

c) crystallization

d) Glass

d) 00 C

39. Dependence of the rate of homogeneous visco-plastic flow of AMC external stress σ is usually approximated by the function ...

a) = A ∙ σm

b) = const (σ)

c) = 0 ∙ sinh [],

d) = (2 ∙ τ / 0) ∙ exp (-τ/τ0).

d) = 2 ∙ ν ∙ exp (-α ∙ V * / Vf) ∙ exp [-ΔG / (kΔ / k ∙ T)]

40. , Match the designation in the dependence of the rate of flow shear AMC = 0 ∙ sinh [] and their physical meaning.

The physical meaning of symbols

a) temperature

b) the time

c) shear stress

d) the local deformation of the shear

d) the amount of

41. When τ >> τ0 viscosity AMC, is determined by ...

a) η = (2 ∙ τ / 0) ∙ exp (-τ/τ0)

b) η =

a) η =

g) η = τ /

d) η = • exp (τ /)

42. The approach of the nanoparticles under the influence of an external load (select them) ...

a) particles pass to the isotropic state

b) there is a visco-plastic flow of the surface layers

c) is purely elastic compression

d) there are processes of homogenization of the material nanoparticles

d) the temperature reaches the glass transition temperature of nanoparticles

43. Formation of different structural states nanoamorfnyh solids depends on (choose the right) ...

a) The ratio of the layer thickness and particle radius

b) the structural parameters of the surface layers

c) the relative particle size parameters

d) structural parameters of the particles

e) the ratio of viscous-plastic properties of the material layer and the main part of the particle

44. If the concentration of excess free volume in the surface layer of the particles is higher than in the bulk, while the surface layer is enriched with impurities embrittle AMC, the process of sealing a compact will be due to ... the flow of the material of the surface layer.

45. In metal nanosteklah revealed ... characteristic positron lifetime.

a) two

b) three

a) four

d) five

d) Six

46. The second component of the positron lifetime t2 can be associated with ...

a) positron trapping in areas of high concentration of excess free volume

b) the destruction of the concentration inhomogeneities in the boundaries of the particles

c) changes in the structure of homogeneous metallic glasses

d) formation of amorphous layers positron

e) annigilirovaniem positrons

47. Heat treatment of metallic nanostekla second component of the positron lifetime ...

a) has no physical meaning

b) is not taken into account in analytical calculations

c) transformed into a third

r) is equal to the first

d) is the same as the untreated

48. Diffusion kinetics equation alignment with concentration (r, t) in a spherical particle is given by ...

a)

b)

c)

d)

e)

49. At the initial stage of the process kompaktiroaniya when the relative density of the compact ρ <0,9, its seal is due to ...

a) reducing the particle radius

b) an increase in interstitial air

c) increasing the viscosity of the compact set

d) increase the area of contact between the contacting particles necks material

e) healing isolated pores

50. At the end of the process of compacting 0,9 <ρ <1,0 seal compact due ...

a) reducing the particle radius

b) an increase in interstitial air

c) increasing the viscosity of the compact set

d) increase the area of contact between the contacting particles necks material

e) healing isolated pores

51. Neglecting the change in shape of the particles in the initial stage of the compaction rate of increase of the relative density of the compact is ...

a)

b)

c)

d)

e)

53. In the formula, the effective viscosity compact ηef = fη1 + (1-f) η2, f - it's ...

a) the amount of pressure on the CD

b) The coefficient of friction of the particles compact

c) aspect ratio

d) the volume fraction of particles

e) the rate of densification compact

54. Yield strength AMC σT is the Young's modulus ...

a) 12 ... 25

b) 1 ... 1.5

c) 1/3 ... 1/5

d) 1/40 ... 1/50

d) 1/150 ... 1/250

55. Metallic glasses can be obtained using ... amorphous nanofibers.

a) melting

b) pressing

c) electrolysis

d) hydrolysis

e) in an electric arc spraying

56. When alternation-aft nanofibers have the options of decomposition of adjacent layers with respect to each other (select them) ...

a) with a parallel arrangement of fibers

b) the location of cross-fiber

c) the location of the longitudinal-transverse

d) Cross-cross

e) longitudinal-longitudinal

57. An important condition for the massive AMC is to prevent ...

a) the anisotropic structure of nanoparticles

b) The melting

c) fluidized state

d) shear stresses in the compact

d) crystallization

58. The process of nucleation of crystal nucleation starts and develops when the sample is held at AMC a temperature below ...

a) ambient air

b) 00 C

c) boiling water

d) the triple point of water

d) crystallization

59. AMC zavismosti crystallization temperature of the pressure looks like ...

a) T (P) =

b) T (P) = + Tk0

c) T (P) =

d) T (P) = T

e) T (P) =

60. Change in the rate of nucleation in transition by the relation ...

a) tp =

b) V = 2

a) I (t) = I0exp (t / tp)

z) =

e)

61. At present, the pro ¬ industry widely uses various reinforcing and ... on ¬ coating on the basis of the phase of imple ¬ transition metals.

62. On ¬ coating on the basis of the phase of imple ¬ transition metals deposited on metal-cutting tools ¬ ment with a view ...

a) improve the ductility

b) strengthening

c) reduce the hardness

d) protect against corrosion

d) reducing the cost of the tool

63. At present, the pro ¬ industry widely uses various strengthening and protective coating on ¬-based imple ¬ phase of transition ...

64. On ¬ coating on the basis of the phase of imple ¬ transition metal is applied to elements of various construc ¬ struction in order to ...

a) improve the ductility

b) strengthening

c) reduce the hardness

d) protect against corrosion

d) reducing the cost of the tool

65. To improve the performance appraisal prepared to cover ¬ ment subjected to additional processing ¬ tion ... implant ¬ tion.

a) Surface

b) heat

c) cathodic

d) chemical

e) the softening

66. Nitride coatings on titanium ¬ on different substrates can be applied methods (select them) ...

a) gas-phase deposition ¬

b) cathode connection

c) an ion-plasma deposition of ¬

d) vacuum arc at ¬ dusting

d) plasma-magnetron sputtering at ¬

66. Microdiffraction pattern analysis shows that in the cover ¬ TII titanium nitride ¬ to present only one phase with a lattice parameter ...

a) a = 0.23 mm

b) a = 0.432 mm

c) a = 0.627 m

d) a = 0.118 m

d) a = 0.423 nm

67. The lattice parameter in TII cover ¬ ¬ titanium nitride to be equal to a = 0.423 nm and corresponds ... stoichiometric composition.

a) carbon monoxide

b) the crystal lattice

c) titanium

d) Nitrogen

e) titanium nitride

68. Implantation of Ti and Ni in the gas-phase coating of titanium nitride PriVO ¬ in the appearance of a parent ¬ skih beans covered ...

a) titanium oxide

b) the introduction phase of iron nitride ¬

c) subgrain

g) of the substrate

e) non-metallic inclusions

69. Med ¬ average size of subgrains in maternal ¬ skih grains of titanium nitride coatings deposited by chemical vapor deposition, is ...

a) 60 nm

b) 8 nm

c) 25 mm

g) 90 mm

e) 3 cm

70. Med ¬ average size of subgrains in the coating of titanium nitride deposited by ion-plasma spraying is ...

a) 1 nm

b) 10 nm

c) 100 nm

d) 1000 nm

e) 100 m

71. Med ¬ average size of subgrains in the coating of titanium nitride deposited by vacuum arc spraying, equal to ...

a) 1.354 nm

b) 35.55 nm

c) 77.92 nm

g) 200 nm

d) 1 mm

72. Joint ion implantation of titanium and nickel ion-plasma coatings leads to a partial ... local internal stresses in stress ¬ ion-doped zone.

73. During his ¬ ion plantation in surface coating of titanium nitride on the depth of implantation ¬ ented area implanted atoms (select them) ...

a) carbon

b) iron

a) oxygen

g) of helium

e) inert gases

74. , Match the nitride coating method

titanium and micro ¬ rostruktury scheme covers.

a) gas-phase coating

b) vacuum-arc

c) ion-plasma coatings

d) plasma-magnetron coating ¬ ment

d) Auger electron coverage

75. Ion implantation is no less ... and nyaet ¬ ¬ F zovoe state coatings, but lowers ...

a) a system di ¬ faction rings; impurities in the form of carbon and oxygen

b) the amount of impurities in the form of carbon and oxygen, di ¬ faction rings

c) the internal stresses; grain structure

g) of the grain structure, internal stresses

d) a pair of ¬ lattice parameter, the average grain size

76. In Nana ¬ hay active dispersed catalysts ¬ tion phase is represented by the nanoparticles ...

a) noble gases

b) carbon

a) nitrogen

d) non-metallic inclusions

d) metals

77. Nana ¬ hay catalysts were prepared using the operation (select them) ...

a) coagulation of dispersed phases

b) Cathodic refining

a) impregnating the carrier

d) thermal drying

d) recovery

78. Calculation of average particle size of the metal phase by the difference scattering intensities catalyst and carrier is called the ...

a) Auger electron microscopy

b) malouglo ¬ angle scattering of x-rays

c) thin foils

d) vacuum-arc spraying

e) identification of ultrafine phase

79. In the study by Moore is a risk of manifestation ...

a) X-ray scattering

b) the coagulation of dispersed phases

c) the diffraction of protons

d) ef ¬ fects of interference

e) has a crystal lattice

80. To avoid manifestation of interference effects when using SDM pores of the support and catalyst ...

a) bombarded with alpha particles

b) filled with a liquid

c) is removed from the metal

d) negative charge

g) is placed in an electromagnetic field

81. To avoid manifestation of interference effects when using SDM support and catalyst pores filled (select them) ...

a) H2O

b) liquid nitrogen

c) SN2I2

d) SN2Vr2

e) S2N4S12

82. Occurrence of interference effects due to ...

a) a combination of the scattering centers of different nature

b) the presence of liquid in the pores

c) varying degrees of refraction of light

d) lack of atoms of nonmetallic materials

e) varying the electron density at different sites

83. ¬ tion in the study of supported catalysts by MOORE interference effects "particle-pore" ...

a) significantly distort the real picture

b) only appear when the liquid filling of pores

c) does not allow you to apply in practice MOORE

d) are not essential, if the intensity of the scattering of the active phase on the order of a superior, and the carrier scattering

e) no

84. In the transition from single-component catalyst ¬ tori multicomponent difficulties in interpreting ¬ her curves ...

85. The system components Ir-Rh/Si02 concentration ¬ nents ..., electronic density ...

a) vary, the same

b) are equal, vary considerably

c) are equal, identical

d) vary greatly, different

e) do not matter; identically equal

86. Particle in the system Pd Pd-Au-Rh/SiO2 prevail in the range R = ..., which includes a maximum of the distribution curve.

a) 1 ... 2 mm

b) 0.5 ... 4 mm

a) 2 ... 5 nm

d) 56 ... 85 nm

d) 22 ... 50 mm

87. The use of small-angle scattering races ¬ x-rays to obtain information about (b) (choose the right) ....

a) applied one-component dispersion of the metallic phase

b) applied one-component dispersion of the metallic phase

c) the porous structure of the adsorbent carrier

g) changes ¬ neniyah in the catalyst

e) neutron depolarization

88. , Match the position on the diagram and part name.

а) тигель с расплавом

б) сопло

в) расплав

г) лента

д) закалочный диск

е) место схода ленты с диска

89. In stage I of cooling amorphous magnetically tapes at spinning occurs (select them) ...

a) filling the crucible melt

b) quenching the melt

c) formation of amorphous ribbon

d) cooling the already hardening ¬ necks tape to disk

d) cooling the flying disc with tape on the air

90. In stage II cooling amorphous soft magnetic tapes at spinning happens ...

a) filling the crucible melt

b) quenching the melt

c) formation of amorphous ribbon

d) cooling the already hardening ¬ necks tape to disk

d) cooling the flying disc with tape on the air

91. In stage III cooling amorphous soft magnetic tapes at spinning happens ...

a) filling the crucible melt

b) quenching the melt

c) formation of amorphous ribbon

d) cooling the already hardening ¬ necks tape to disk

d) cooling the flying disc with tape on the air

92. Upon receipt of amorphous magnetic alloys based on cobalt occurrence of structural anisotropy in the film along its axis in the direction of motion occurs at ...

a) The first stage

b) the first and second stages

c) the second stage

d) the second and third stage

e) The third stage

e) at all three stages

93. Particular feature of ¬ formation of amorphous ribbons with spinning is that after leaving the "puddles" tape ...

a) has a larger width

b) becomes isotropic structure

c) is obtained from nanotolschinoy

d) can not be used in the industry

e) attaches to the drive

94. Formation ¬ tion of the magnetic domain structure under the influence of residual stresses and the formation ¬ Rovani structure-sensitive properties is the ...

a) The first stage

b) the first and second stages

c) the second stage

g) a second or third stage

e) The third stage

e) at all three stages

95. In ¬ formation vanii magnetic anisotropy in an amorphous magnetic alloys based on cobalt spinning play the main role (choose the right) ...

a) the temperature of the tape at the exit from the drive

b) the Curie temperature

c) the disk material

d) presence of a seed

e) the diameter of the disc

96. Increase the duration of spinning and casting temperature on receipt of amorphous magnetic alloys based on cobalt spinning (select them) ...

a) reduce the rate of cooling

b) increase the temperature of the tape drive to the vanishing point

c) make it necessary to reverse the rotation of the disk

d) forming a non-magnetic structure in tape

d) reduce the DT

97. To obtain a large temperature difference AT = TC-TLC in the contact area of the amorphous soft magnetic tape drive quenching needed (choose the right) ...

a) thermal conductivity and increased its disc diameter

b) low temperature casting so ¬

c) a small strip thickness (<20 microns)

d) small initial portion of the tape length

d) alloys with high Curie

98. Set the sequence of the technological cycle of obtaining nanolaminatov.

a) hot rolling in a vacuum package

b) The compilation is defined ¬ tion of the number of plates

c) obtaining a thickness equal to the thickness of the first initial ¬ one of the original plates, ¬ ing composite component

g) cold rolling on air ¬ heh

e) The processing of plates grit

99. The heterogeneity of the layers in thickness nanolaminata increases with ...

a) the total strain

b) the processing temperature

c) the metal content

d) the time of his exposure

e) the rate of cooling

100. The dependence of solid achievement ¬ composite Cu-Ni on the true strain ¬ tion by rolling in the 2nd, 3rd and 4th cycle is close to the ...

a) the hyperbolic nature

b) the nature of the parabolic

c) the linear nature

d) sinusoidal

e) the nature of the tangential

101. The spectrum of the nanocomposite that ¬ Cu-Ni copper line shifted toward ...

a) copper

b) nickel

a) iron

d) oxygen

d) carbon

102. During the vacuum rolling nanocomposite Cu-Ni diffusion ¬ manifold nickel to copper leads to the formation of solid solutions based on the pa ¬ ...

a) copper

b) nickel

a) iron

g) of carbon

d) oxygen

103. During the vacuum rolling nanocomposite Cu-Ni assess the depth of penetration of the diffusion well ¬ ¬ veniya nickel atoms in the copper can, using the expression ...

a) L = RTlnK

b) L =

a) L =

g) L =

d) L = a • b • lnR

104. By vacuum rolling a laminated structure consisting of layers of the same metal, it is impossible, if not to take measures to eliminate the ...

a) ¬ a hysteresis loop depending permeability and selectivity ¬ ciency nanolaminata

b) Release of volatile oxides nanolaminata during heat treatment

c) the solubility of the metal in the atmosphere

d) direct diffusion ¬ onnogo contact between the layers

e) allotropic metal used

105. The process of grain growth in nano-and microcrystalline metals near the onset temperature of crystallization is ... character.

106. Near the temperature of the onset of recrystallization in the nano-and microcrystalline metals upsize only some grain volume fraction during annealing at ¬ melted by ...

a) a sinusoidal dependence

b) the nature of the tangential

c) the exponential

d) a linear relationship

e) the closed-loop

107. Analysis of the grain size distribution shows that near the recrystallization temperature of the distribution function of grain size becomes ... a hundred ¬ - it appears to the Executive ¬ maximum corresponding to the abnormally growing grains.

108. Problem description ¬ of abnormal growth in the nano-and microcrystalline metals is closely linked to the problem description ...

a) The process of recrystallization

b) the volume fraction of fine particles

c) the average grain size

d) The melting of nanomaterials

e) the process of making nanomaterials

109. According to the classical ¬ skim a certain temperature, at which the growth centers of recrystallization ¬ tion - is the temperature ...

a) recrystallization

b) annealing

a) melting

d) the transition from liquid to solid

e) the Curie

110. Temperature started Resort Non ¬ crystallization in pure metals depends on (select them) ... many factors, first of all, from ...

a) the chemical composition of the material

b) the phase composition of the material

c) the degree of deformation penalties ¬

d) rate of deformation

d) temperature

111. Caused dislocations in nano-and microcrystalline metals (select them) ...

a) create a field of internal stresses them ¬

b) create additional free volume of grain boundaries

a) reduce the hardness

g) prevent the move ¬ scheniyu grain boundaries

d) cause ano ¬ mal grain boundary diffusion

112. Reduction in the density of defects in the grain boundaries during annealing of nano-and microcrystalline metals leads to ...

a) reduction of the fields inside them stress ¬

b) reduce the extra free volume of grain boundaries

a) reduce the hardness

g) prevent the move ¬ scheniyu grain boundaries

d) decreases the yield strength

113. ... In the nano-and microcrystalline metals - is free of defects sites matrix ca ¬ servation of large-boundaries are capable of migration.

114. The average grain size d * in the nano-and microcrystalline metals is related to the size of small and large grains d D ratio ...

a) d * = (1 + f) • d + f • D

b) d * = f • d + (1-f) • D

a) d * = f • d / • D

g) d * = D / (d + D)

d) d * = (1-f) • D

115. The third stage of the grain growth in nano-and microcrystalline metals comes after ...

a) the "liberation" of the boundaries of large grains of at ¬ piling up in them during the migration defect ¬ Comrade

b) an increase in the volume fraction of fine grains (up to 0.2)

c) the increase of the volume fraction of fine grains f> 0,8

d) heating the material to a temperature of solidus

d) applying pressure to the material (P = 1 atm)

116. Characteristic of amorphous alloys is (choose the right) ...

a) low strength

b) high strength

c) high ductility

d) low ductility

d) low fracture toughness

117. The most effective method of obtaining a house ¬ amorphous alloys in the form of tape thickness of 30 ... 40 mm with high mechanical properties is ¬ Skim ...

a) cutting of the plates

b) quenching from the liquid state

c) slow crystallization of the molten alloy

g) of workpieces on machine tools

e) forging of blanks

118. The specificity of the method of producing amorphous alloy by quenching from the liquid to conclude ¬ prises sharp hardened races ¬ swimming at ...

a) ~ 102 K / s

b) ~ 103 K / s

c) ~ 104 K / s

d) ~ 105 K / s

e) ~ 106 K / s

119. Metal ¬ tal component of the composite metal-plastic must have (choose the right) ...

a) high strength

b) a low pla ¬ stichnost

c) a satisfactory adhesive strength

d) a corrosion stand ¬ bone

e) contain the minimum number of de ¬ fitsitnyh

120. The introduction of nickel-based amorphous alloys Fe-P and Fe-Si-P-B primarily raises ...

a) strength

b) the hardness

c) ductility

d) wear

d) temperature brittleness

121. Fractographic studies of alloys show that the initially amorphous alloys exhibit ... absolutely smooth cleavage.

122. In multilayer composites based plastics, amorphous ribbon layers 5, the layers of composite foundation ¬ that will be ...

a) 2

b) 4

a) 5

g) 6

e) an unlimited number of

123. Fractographic studies composition ¬ Comrade based plastics after uniaxial tensile tests show that the failure of the substrate occurs after every ¬ violation ...

Keys of correct answers

№№ вопросов |

Коды правильных ответов |

№№ вопросов |

Коды правильных ответов |

№№ вопросов |

Коды правильных ответов |

1 |

а, б, в, г, д |

2 |

а, б, г, д |

3 |

д |

4 |

а, б, в, г, д |

5 |

а, в, г |

6 |

в |

7 |

г |

8 |

г |

9 |

б |

10 |

а, б, в, г, д |

11 |

а, б, в, д |

12 |

в |

13 |

а, б, в, г |

14 |

а, б, в, г, д |

15 |

а, б, г, д |

16 |

д |

17 |

д |

18 |

в |

19 |

а |

20 |

а |

21 |

а, б, г, |

22 |

б |

23 |

б, в, г |

24 |

в |

25 |

а, б, в, д |

26 |

б |

27 |

б |

28 |

а, б, в, г, д |

29 |

а, в, г, д |

30 |

в |

31 |

а, г, д |

32 |

б |

33 |

в |

34 |

д |

35 |

б |

36 |

д |

37 |

б |

38 |

д |

39 |

а |

40 |

в |

41 |

а, б, в, г, д |

42 |

г |

43 |

д |

44 |

а, г |

45 |

б, е |

46 |

а, д |

47 |

г, д |

48 |

в |

49 |

а |

50 |

в |

51 |

г |

52 |

в |

53 |

1-б, 2-г, 3-з, 4-д, 5-е, 6-в, 7-ж, 8-а |

54 |

а, б, в, г, д |

55 |

а, б, г |

56 |

а |

57 |

в |

58 |

б |

59 |

г |

60 |

в |

61 |

д |

62 |

а |

63 |

а, б, в, г, д |

64 |

в |

65 |

а |

66 |

б |

67 |

а, б, в, г, д |

68 |

г |

69 |

а |

70 |

д |

71 |

а |

72 |

б, г |

73 |

1 – а, в, д 2 – б, г |

74 |

б |

75 |

а |

76 |

а |

77 |

в |

78 |

в |

79 |

г |

80 |

д |

81 |

б |

82 |

а |

83 |

г |

84 |

г |

85 |

б |

86 |

а, б, в, г |

87 |

д |

88 |

а - 4, в – 3, г - 1, д - 2 |

89 |

б |

90 |

в |

91 |

а |

92 |

г |

93 |

д |

94 |

в |

95 |

а, б, в, г, д |

96 |

б |

97 |

б, в |

98 |

а, г |

99 |

а, б, г |

100 |

а, б, д |

101 |

а |

102 |

а |

103 |

в |

104 |

б |

105 |

г |

106 |

б, г, д |

107 |

а |

108 |

д |

109 |

а, б, г, д |

110 |

б |

111 |

а |

112 |

б |

113 |

а |

114 |

б |

115 |

д |

116 |

г |

117 |

а |

118 |

а, в, г, д |

119 |

д |

120 |

д |

121 |

в |

122 |

а |

123 |

в |

124 |

г |

|

|

|

|