- •Give the definition of the stream line, write its differential equation.

- •Give the definition of the stream surface, infinitesimal stream tube.

- •Essence of Eulers method for investigation of fluid motion .

- •Essence of Lagrange method for investigation of fluid motion .

- •Accordance between path line, streamline, Eulers and Lagrange methods for investigation of fluid motion

- •What is the base for obtaining continuity equation?

- •Write integral form of continuity equation and call its members.

- •Write differential form of continuity equation and call its members.

- •Write differential form of continuity equation for steady flow and call its members.

- •Write differential form of continuity equation for incompressible flow and call its members.

- •W rite continuity equation for infinitesimal stream tube, one dimensional flow with finite cross section area and call its members.

- •Which physical values are considered as gas state parameters?

- •Write the gas state equation and call its members.

- •Give the definition of the gas compressibility; which index is used in order to characterize compressibility.

- •Give the definition of the gas viscosity; which index is used in order to characterize viscosity.

- •Write the Newton’s formula for internal friction and call its members.

- •Write formula for calculation Reynolds number (Re). Call its members.

- •Write the formula for calculation the speed of sound using gas temperature; and call its members.

- •How (quality) does change dynamic coefficient of viscosity when temperature of gas changes? The same for liquid.

- •Call physical values whose fields completely describe the phenomenon of flow around the solid body.

- •Which type of thermodynamic process in aerodynamics usually is used ? Call this thermodynamic process, write its formula, call members of this formula.

- •Write formulas for calculation gas parameter relation in flow stagnation point and free stream condition. Call members of these formulas.

- •Give the definition the critical or sonic flow regime.

- •What is critical speed of sound?

- •Write formula for calculation theoretical maximum speed of flow and call its members.

- •What is the velocity factor? What is difference between the velocity factor and Mach number?

- •Write formula for calculation flight Mach number using instrumental measured pressure values.

- •Call the conformity between flight regimes and Mach number values. Subsonic and Supersonic speed

- •Write Gugonio equation, call its members.

- •Name and give definitions of two viscosity flow regimes.

- •Give the definition of the boundary layer.

- •Draw schemes of viscose air flow about solid body surface. Mark main elements of this flow.

- •Relation between which forces does Reynolds number (Re) characterize? Write the formula for Reynolds number calculation, call physical values used in this formula.

- •Relation between which forces does Fruds number (Fr) characterize? Write the formula for Fruds number calculation, call physical values used in this formula.

- •Relation between which forces does Eulers (Eu) number characterize? Write the formula for Eulers number calculation, call physical values used in this formula.

- •Relation between which forces does Mach number (m) characterize? Write the formula for Mach number calculation, call physical values used in this formula.

- •Relation between which forces does Struhal number (St) characterize? Write the formula for Struhal number calculation, call physical values used in this formula.

- •Relation between which forces does turbulance degree (ε) characterize?

Write formula for calculation flight Mach number using instrumental measured pressure values.

The Mach number at which an aircraft is flying at can be calculated by

where:

is Mach number

is velocity of the moving aircraft and

is the speed of sound at the given altitude

Note that the dynamic pressure can be found as:

![]()

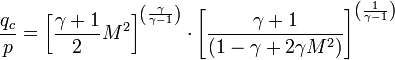

Assuming air to be an ideal gas, the formula to compute Mach number in a subsonic compressible flow is derived from Bernoulli's equation for M<1:[7]

where:

![]() is impact

pressure (dynamic

pressure) and

is impact

pressure (dynamic

pressure) and

![]() is static

pressure

is static

pressure

![]() is

the ratio

of specific heat of

a gas at a constant pressure to heat at a constant volume (1.4 for

air).

is

the ratio

of specific heat of

a gas at a constant pressure to heat at a constant volume (1.4 for

air).

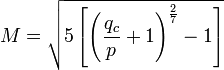

The formula to compute Mach number in a supersonic compressible flow is derived from the Rayleigh Supersonic Pitot equation:

Calculating Mach Number from Pitot Tube Pressure

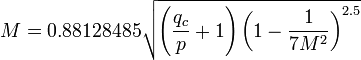

At altitude, for reasons explained, Mach number is a function of temperature. Aircraft flight instruments, however, operate using pressure differential to compute Mach number, not temperature. The assumption is that a particular pressure represents a particular altitude and, therefore, a standard temperature. Aircraft flight instruments need to operate this way because the stagnation pressure sensed by a Pitot tube is dependent on altitude as well as speed.

Assuming air to be an ideal gas, the formula to compute Mach number in a subsonic compressible flow is found from Bernoulli's equation for M<1 (above):[7]

The formula to compute Mach number in a supersonic compressible flow can be found from the Rayleigh Supersonic Pitot equation (above) using parameters for air:

where

![]() is

dynamic pressure measured behind a normal shock

is

dynamic pressure measured behind a normal shock

Call the conformity between flight regimes and Mach number values. Subsonic and Supersonic speed

If the mach number is < 1, the flow speed is lower than the speed of sound - and the speed is subsonic.

If the mach number is ~ 1, the flow speed is approximately like the speed of sound - and the speed is transonic.

If the mach number is > 1, the flow speed is higher than the speed of sound - and the speed is supersonic.

If the mach number is >> 1, the flow speed is much higher than the speed of sound - and the speed is hypersonic.

Write Gugonio equation, call its members.

Gugonio

equation is

What channel is named Laval’s nozzle, what is its destination?

A de Laval nozzle (or convergent-divergent nozzle, CD nozzle or con-di nozzle) is a tube that is pinched in the middle, making a carefully balanced, asymmetric hourglass-shape. It is used to accelerate a hot, pressurized gas passing through it to a supersonic speed, and upon expansion, to shape the exhaust flow so that the heat energy propelling the flow is maximally converted into directed kinetic energy. Because of this, the nozzle is widely used in some types of steam turbines, and is used as a rocket engine nozzle. It also sees use in supersonic jet engines.

Similar flow properties have been applied to jet streams within astrophysics.[1]

History

The nozzle was developed by Swedish inventor Gustaf de Laval in 1888 for use on a steam turbine.[2][3][4][5]

This principle was first used in a rocket engine by Robert Goddard. Very nearly all modern rocket engines that employ hot gas combustion use de Laval nozzles.

Operation

Its operation relies on the different properties of gases flowing at subsonic and supersonic speeds. The speed of a subsonic flow of gas will increase if the pipe carrying it narrows because themass flow rate is constant. The gas flow through a de Laval nozzle is isentropic (gas entropy is nearly constant). At subsonic flow the gas is compressible; sound, a small pressure wave, will propagate through it. At the "throat", where the cross sectional area is a minimum, the gas velocity locally becomes sonic (Mach number = 1.0), a condition called choked flow. As the nozzle cross sectional area increases the gas begins to expand and the gas flow increases to supersonic velocities where a sound wave will not propagate backwards through the gas as viewed in the frame of reference of the nozzle (Mach number > 1.0).

Analysis of gas flow in de Laval nozzles

The analysis of gas flow through de Laval nozzles involves a number of concepts and assumptions:

For simplicity, the gas is assumed to be an ideal gas.

The gas flow is isentropic (i.e., at constant entropy). As a result the flow is reversible (frictionless and no dissipative losses), and adiabatic (i.e., there is no heat gained or lost).

The gas flow is constant (i.e., steady) during the period of the propellant burn.

The gas flow is along a straight line from gas inlet to exhaust gas exit (i.e., along the nozzle's axis of symmetry)

The gas flow behavior is compressible since the flow is at very high velocities (Mach number > 0.3).

Exhaust gas velocity

As the gas enters a nozzle, it is traveling at subsonic velocities. As the throat contracts down the gas is forced to accelerate until at the nozzle throat, where the cross-sectional area is the smallest, the linear velocity becomes sonic. From the throat the cross-sectional area then increases, the gas expands and the linear velocity becomes progressively more supersonic.

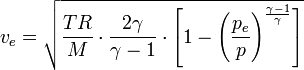

The linear velocity of the exiting exhaust gases can be calculated using the following equation:[6][7][8]

-

where:

= Exhaust velocity at nozzle exit, m/s

= absolute temperature of inlet gas, K

= Universal gas law constant = 8314.5 J/(kmol·K)

= the gas molecular mass, kg/kmol (also known as the molecular weight)

=

= isentropic

expansion factor

= isentropic

expansion factor

= specific heat of the gas at constant pressure

= specific heat of the gas at constant volume

= absolute pressure of exhaust gas at nozzle exit, Pa

= absolute pressure of inlet gas, Pa