- •Передмова

- •Contents

- •Unit 1. Materials handling

- •Material Holding, Feeding and Metering

- •Hand chain hoists are portable lifting devices suspended from a hook and operated by _______ on a hand chain.

- •Unit 2. Gear and gearing (Part 1)

- •Gear and Gearing (part 1)

- •Unit 3. Geared systems and mechanisms (Part 2)

- •Gears and Gearing

- •Important, stock, reduced, figures, to be left,

- •Getting into shape: some basics

- •Unit 4. Metal-removal processes and machine tools

- •Material Removal Processes

- •Manufacturing techniques evaluation: cutting operations

- •Unit 5. Motion control systems overview

- •Motion Control System

- •Installation, shaft, servomotor, smooth, force, unit accumulate

- •Unit 6. Tool wear and sharpening

- •Tool wear

- •Unit 7. Bearings

- •Bearings. Components and specifications

- •Fig.1 Radial contact bearing terminology.

- •Principal standard bearing types

- •Unit 8. Mechanical elements (Part 1)

- •Machine Elements: Keys and Pins

- •Unit 9. Mechanical elements (Part 2)

- •Mechanical Elements: Rivets, Belts and Pulleys.

- •Write a list of all fasteners that you know. Compare it with the one of your groupmate.

- •Give the definition to the following terms and make sentences of your own with each of them:

- •Imagine that you are a young crazy inventor and someone presented you a large sum of money. In what field of science would you invest them or what would you do?

- •Unit 10. Mechanical failure modes

- •Mechanical Failure Modes

- •References:

- •How to make a presentation

- •Key phrases for preparing presentation

- •Why is writing an essay

- •Technical translation

- •Methods and Practices

- •Reading techniques

- •Skimming

- •Scanning

- •Using Context

- •Writing techniques

- •The Introduction

- •The body Paragraphs

- •The Conclusion

- •Irregular verbs

Unit 4. Metal-removal processes and machine tools

T ask 1. Discuss the following question:

How do various types of machine-tools differ from each other?

That’s how we usually ask and answer questions in English. Study this table.

QUESTION TECHNIQUE: Do you happen to know … I wonder if … Could you (possibly) tell me … I’d like to know … One more question (to you) … |

ANSWERING TECHNIQUE: Well … Let me think … I don’t know exactly … I’m not sure … It seems to me … As for me … |

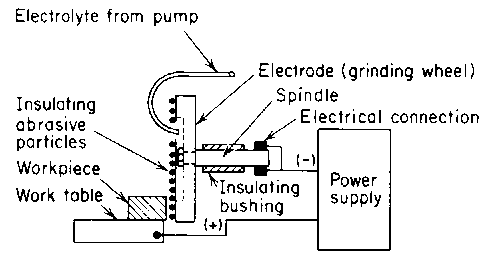

Task 2. Look at the schematic diagram. Try to explain the electrochemical grinding process.

Task 3. Listen and complete the TV advert.

T his is the new Multi Tool!

Use it at home. Use it on the building site. Use it when you travel. It has a 1) _______ and a pair of 2) ________ . It also has a 3) ______, a 4) ________ and a 5) ________ ________ .

The Multi Tool has everything you need! Only £29.99. Buy one now!

Task 4. Read and translate the following text.

Material Removal Processes

Material removal processes, which include machining, cutting, grinding, and various nonmechanical chipless processes, are desirable or even necessary for the following basic reasons: closer dimensional tolerances, surface roughness, or surface-finish characteristics may be required than are available by casting, forming, powder metallurgy, and other shaping processes; and part geometries may be too complex or too expensive to be manufactured by other processes. However, material removal processes inevitably waste material in the form of chips, production rates may be low, and unless carried out properly, the processes can have detrimental effects on the surface properties and performance of parts.

Traditional material removal processes consist of turning, boring, drilling, reaming, threading, milling, shaping, planing, and broaching, as well as abrasive processes such as grinding, ultrasonic machining, lapping, and honing.

A factor of great significance in metal cutting is tool wear. Many factors determine the type and rate at which wear occurs on the tool. The major critical variables that affect wear are tool temperature, type and hardness of tool material, grade and condition of workpiece, abrasiveness of the microconstituents in the workpiece material, tool geometry, feed speed, and cutting fluid. The type of wear pattern that develops depends on the relative role of these variables.

Tool wear can be classified as flank wear; crater wear on the tool face; localized wear, such as the rounding of the cutting edge; chipping or thermal softening and plastic flow of the cutting edge; concentrated wear resulting in a deep groove at the edge of a turning tool, known as wear notch.

The general types of machine tools are lathes; turret lathes; screw, boring, drilling, reaming, threading, milling, and gear-cutting machines; planers and shapers; broaching, cutting-off, grinding, and polishing machines. Each of these is subdivided into many types and sizes.

Turning is a machining operation for all types of metallic and nonmetallic materials and is capable of producing circular parts with straight or various profiles. The cutting tools may be single-point or form tools. The most common machine tool used is a lathe; modern lathes are computer-controlled and can achieve high production rates with little labor.

Boring is a machining process for producing internal straight cylindrical surfaces or profiles, with process characteristics and tooling similar to those for turning operations. Boring machines are of two general types, horizontal and vertical, and are frequently referred to as horizontal boring machines and vertical boring and turning mills. A classification of boring machines comprises horizontal boring, drilling, and milling machines; vertical boring and turning mills; vertical multispindle cylinder boring mills; vertical cylinder boring mills; vertical turret boring mills; car-wheel boring mills; diamond or precision boring machines; and jig borers.

Drilling is a commonly employed hole-making process that uses a drill as a cutting tool for producing round holes of various sizes and depths. Drilled holes may be subjected to additional operations for better surface finish and dimensional accuracy, such as reaming and honing. Drilling machines are intended for drilling holes, tapping, counter boring, reaming, and general boring operations. They may be classified into a large variety of types: twist drills, straight-shank twist drills, taper-shank drills, heavy-duty drill, and radial drill.

A reaming is a multiple-cutting edge tool used to enlarge or finish holes, and to provide accurate dimensions as well as good finish. Reamers are of two types: 1)rose and 2) fluted. The rose reamer is a heavy-bodied tool with end cutting edges. It is used to remove considerable metal and to true up a hole preparatory to flute reaming. It is similar to the three- and four-fluted drills. Wide cylindrical lands are provided back of the flute edges.

Threads may be formed on the outside or inside of a cylinder or cone with single-point threading tools, with threading chasers, with taps, with dies, by thread milling, by thread rolling, and by grinding. There are numerous types of taps, such as hand, machine screw, pipe, and combined pipe tap and drill. Small taps usually have no radial relief. Large taps may have still more flutes.

Milling is one of the most versatile machining processes and is capable of producing a variety of shapes involving flat surfaces, slots, and contours (Fig. 1)

Fig. 1 Basic types of milling cutters and operations. (a) Slab (peripheral) milling; (b) face milling; (c) end milling.

Task 5. Ask your groupmate about the objects in the picture below. Translate the terms and describe the differences between these types of drills. If you have problems contact the dictionary or any Internet resources.

Task 6. Read the text again to decide if the following statements are true or false. Correct the false ones.

1. The main features of the broach are the chip clearance, degree of taper or increase in height of each successive tooth, relief, tooth depth, and rake.

2. The heavier the feed per tooth or the longer the surface being broached, the greater must be the pitch or space between successive teeth for the chips to accumulate.

3. Knee-type machines are made with horizontal or vertical spindles.

4. Straight milling machines with fixed or sliding heads are otherwise similar to the horizontal type.

5. They are used for face or end milling and are frequently provided with a rotary table for making cylindrical surfaces.

6. These machines are usually provided with work-holding fixtures and may be constructed as plain or multiple-spindle machines, simple or duplex.

7. Thread millers are used to cut broach and worms.

8. A single formed cutter may be used or all the threads may be cut at one time by a multiple-thread cutter.

Statement |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

T |

|

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

Task 7. Match the verbs and their meanings.

A |

B |

1. to pick (up) |

a) to collect and keep for future use |

2. to fit in |

b) to take hold of or lift |

3. to punch (on) |

c) to make holes on surfaces |

4. to turn on (off) |

d) be in a suitable relation |

5. to store |

e) to start (on, off) |

Task 8. Choose the best alternative to fill in the gaps in each of the following sentences.

1. The horizontal universal _____________ have a swiveling table for cutting helices.

a) machines |

b) devices |

c) equipment |

2. Planer-type millers are used only on the ____________ work.

a) heaviest |

b) harder |

c) better |

3. Plain are produced by inserting the cutter into the bore to be milled, feeding it to depth radially, making a sweeping ___________ about the bore, and withdrawing first radially and then axially.

a) cut |

b) rise |

c) bind |

4. In planetary milling machines the ___________ is stationary on the bed or clamped to the tailstock while the cutter rotates.

a) equipment |

b) workpiece |

c) tools |

5. The plain machines are used for jobbing or ___________ work, the universal for toolroom work.

a) production |

b) output |

c) manufacturing |

6. The fixed-bed machines have a ____________ mounted in a head dovetailed to and sliding on the face of the column.

a) spring |

b) spindle |

c) broach |

7. Rotary-type millers usually have __________ table on which fixtures carrying the workpiece are mounted.

a) a rotating |

b) a threading |

c) a rolling |

8. In hardening, they are often heated in a vertical ___________ furnace and quenched by being hung in an air blast furnished from small holes along the side of pipes placed vertically about the broach.

a) conical |

b) cylindrical |

c) rectangular |

9. Broaches of complicated _________ are likely to warp during the heat-treating process.

a) triangle |

b) workpiece |

c) shape |

10. The pitch should be as coarse as possible to provide ample chip _________, but at least two teeth should be in contact with the workpiece at all times.

a) durability |

b) clearance |

c) cuttering |

Task 9. Complete the sentences using the wordlist below. Use each word only once:

float, permit, normal, provide, interchangeably, grindings, cutting, tool, rigidly,

adjusting, shells, use, to ensure, piloted, tailstock

Expansion reamers 1) ________ a slight expansion by a wedge so that the reamer may be resharpened to its 2) ________ size or for job shop 3) ________; they 4) ________ slight variations in size. Adjustable reamers have means of 5) ________ inserted blades so that a definite size can be maintained through numerous 6) ________ and fully worn blades can be replaced with new ones. Shell reamers constitute the 7) ________ portion of the 8) ________ which fits 9) ________ on arbors to make many sizes available or to make replacement of worn-out 10) ________ less costly. Reamers 11) ________ in their holding fixtures 12) ________ alignment, or they should be 13) ________ in guide bushings above and below the work. They may also be held 14) ________ , such as in the 15) ________ of a lathe.

Task 10. Match the first part of the sentence (1-7) with the second one (a-g):

1) Drilling may affect the mechanical properties of …

2) This causes the workpiece to become more susceptible to …

3) Chips may be long spirals or small flakes, depending on …

4) The type of chips formed can be an indicator of the machinability of …

5) When possible drilled holes should be located perpendicular to …

6) This minimizes the drill bit's tendency to "walk", that is, to be …

7) The higher the length-to-diameter ratio of the ...

… the workpiece surface.

… corrosion at the stressed surface.

… the workpiece by creating low residual stresses around the hole opening.

… drill bit, the higher the tendency to walk.

… the material, with long gummy chips reducing machinability.

… deflected, which causes the hole to be misplaced.

… the material, and process parameters.

Task 11. Translate the following sentences into Ukrainian:

1. Replacement chasers are used in die heads and may be of the fixed or self-opening type.

2. Emulsions and oils are satisfactory for most threading operations.

3. The horizontal type is made for both precision work and general manufacturing.

4

.

The machine is universal and has a wide range of speeds and feeds,

for a face-mill operation may be followed by one with a

small-diameter drill or end mill.

.

The machine is universal and has a wide range of speeds and feeds,

for a face-mill operation may be followed by one with a

small-diameter drill or end mill.

5. Vertical boring mills are adapted to a wide range of faceplate work that can be revolved.

6. The pitch of the teeth, i.e., the distance from one tooth to the next, depends upon tooth strength, length of cut, shape and size of chips, etc.

7. The root should be a smooth curve.

8. A jig-boring machine has a single-spindle sliding head mounted over a table adjustable longitudinally and transversely by lead screws which roughly locate the work under the spindle.

9. Precision setting of the table may be obtained with end measuring rods, or it may depend only on the accuracy of the lead screw.

10. These machines, made in various sizes, are used for accurately finishing holes and surfaces in definite relation to one another.

11. The latter are held in an adjustable boring head by which the tool can be moved eccentrically to change the diameter of the hole.

12. Precision-boring machines may have one or more spindles operating at high speeds for the purpose of boring to accurate dimensions such surfaces as wrist-pin holes in pistons and connecting-rod bushings.

Task 12. Complete the following statements from column A with the corresponding terminations from column B.

A B |

|

1. Vertical drilling machines are usually designated by a dimension which roughly indicates… |

a) …feed drive, are constructed with a box-type column instead of the older cylindrical column. |

2. Heavy-duty drill presses of the vertical type, with all-geared speed and… |

b) …different manufacturers will be interchangeable in the user's plants. |

3. If the web is increased gradually in thickness from point to shank to increase the strength, it is…

|

c) …the diameter of the largest circle that can be drilled at its center under the machine. |

4. Tolerances have been set on the various features of all drills so that the products of…

|

d) …available in metric dimensions. |

5. Larger drills are made by various drill manufacturers and…

|

e) …point to shank (back taper) to prevent binding. |

6. Twist drills, straight-shank twist drills, taper-shank drills are the most common tools used…

|

f) …by the length of the arm. |

7. Twist drills are decreased in diameter from… |

g) …in drilling and are made in many sizes and lengths. |

8. The size of a radial drill is designated… |

h) …customary to reduce the helix angle as it approaches the shank. |

Task 13. Complete the following training material for graduate engineers using the words in the box. Use each word only once.

Drilling Flame-cutting Milling Sawing Shearing |