- •Передмова

- •Contents

- •Unit 1. Materials handling

- •Material Holding, Feeding and Metering

- •Hand chain hoists are portable lifting devices suspended from a hook and operated by _______ on a hand chain.

- •Unit 2. Gear and gearing (Part 1)

- •Gear and Gearing (part 1)

- •Unit 3. Geared systems and mechanisms (Part 2)

- •Gears and Gearing

- •Important, stock, reduced, figures, to be left,

- •Getting into shape: some basics

- •Unit 4. Metal-removal processes and machine tools

- •Material Removal Processes

- •Manufacturing techniques evaluation: cutting operations

- •Unit 5. Motion control systems overview

- •Motion Control System

- •Installation, shaft, servomotor, smooth, force, unit accumulate

- •Unit 6. Tool wear and sharpening

- •Tool wear

- •Unit 7. Bearings

- •Bearings. Components and specifications

- •Fig.1 Radial contact bearing terminology.

- •Principal standard bearing types

- •Unit 8. Mechanical elements (Part 1)

- •Machine Elements: Keys and Pins

- •Unit 9. Mechanical elements (Part 2)

- •Mechanical Elements: Rivets, Belts and Pulleys.

- •Write a list of all fasteners that you know. Compare it with the one of your groupmate.

- •Give the definition to the following terms and make sentences of your own with each of them:

- •Imagine that you are a young crazy inventor and someone presented you a large sum of money. In what field of science would you invest them or what would you do?

- •Unit 10. Mechanical failure modes

- •Mechanical Failure Modes

- •References:

- •How to make a presentation

- •Key phrases for preparing presentation

- •Why is writing an essay

- •Technical translation

- •Methods and Practices

- •Reading techniques

- •Skimming

- •Scanning

- •Using Context

- •Writing techniques

- •The Introduction

- •The body Paragraphs

- •The Conclusion

- •Irregular verbs

Unit 3. Geared systems and mechanisms (Part 2)

Task 1. What is the role of mechanisms in the modern world and what do you know from its history? Have you ever tried to mend your bicycle? What mechanical parts of it can you name?

Task 2. Study the following words. Make sure you know the meaning and translation of them.

a gear, to mesh, teeth, translation motion, rotation, angle, torque, transmission, ratio, pulley, pitch, magnitude, rack, wheel, slip, verify, shape, injection, resistant.

Task 3. Read the text and translate all unfamiliar words.

Gears and Gearing

A gear or more correctly a "gear wheel" is a rotating machine part having cut teeth, or cogs, which mesh with another toothed part in order to transmit torque. Two or more gears working in tandem are called a transmission and can produce a mechanical advantage through a gear ratio and thus may be considered a simple machine. Geared devices can change the speed, magnitude, and direction of a power source. The most common situation is for a gear to mesh with another gear, however a gear can also mesh a non-rotating toothed part, called a rack, thereby producing translation instead of rotation.

The gears in a transmission are analogous to the wheels in a pulley. An advantage of gears is that the teeth of a gear prevent slipping. When two gears of unequal number of teeth are combined a mechanical advantage is produced, with both the rotational speeds and the torques of the two gears differing in a simple relationship.

In transmissions which offer multiple gear ratios, such as bicycles and cars, the term gear, as in first gear, refers to a gear ratio rather than an actual physical gear. The term is used to describe similar devices even when gear ratio is continuous rather than discrete, or when the device does not actually contain any gears, as in a continuously variable transmission.

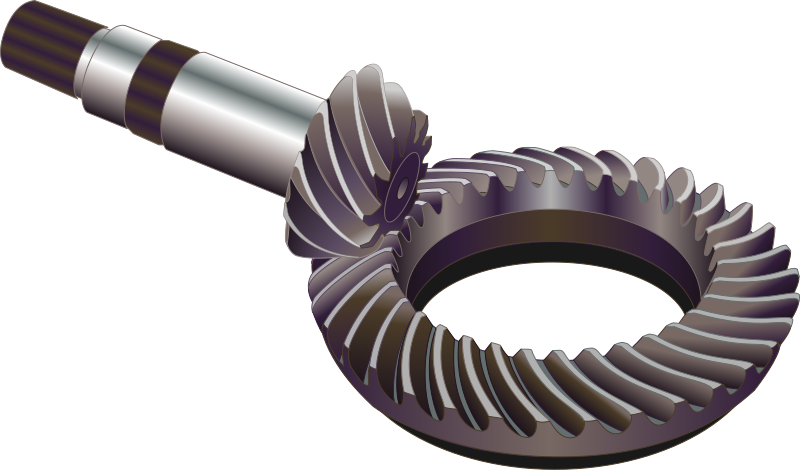

An external gear is one with the teeth formed on the outer surface of a cylinder or cone. Conversely, an internal gear is one with the teeth formed on the inner surface of a cylinder or cone. For bevel gears, an internal gear is one with the pitch angle exceeding 90 degrees. Internal gears do not cause direction reversal.

Numerous nonferrous alloys, cast irons, powder-metallurgy and plastics are used in the manufacture of gears. However steels are most commonly used because of their high strength to weight ratio and low cost. Plastic is commonly used where cost or weight is a concern. A properly designed plastic gear can replace steel in many cases because it has many desirable properties, including dirt tolerance, low speed meshing, and the ability to "skip" quite well. Manufacturers have employed plastic gears to make consumer items affordable in items like copy machines, optical storage devices, VCRs, cheap dynamos, consumer audio equipment, servo motors, and printers.

Gears are most commonly produced via hobbing, but they are also shaped, broached, cast, and in the case of plastic gears, injection molded. For metal gears the teeth are usually heat treated to make them hard and more wear resistant while leaving the core soft and tough. For large gears that are prone to warp a quench press is used. Gear geometry can be inspected and verified using various methods such as industrial CT scanning, coordinate-measuring machines, white light scanner or laser scanning. Particularly useful for plastic gears, industrial CT scanning can inspect internal geometry and imperfections such as porosity.

Task 4. Read the text again and decide whether the following statements are true or false. Correct the false statements.

Two or more gears working in tandem can produce a mechanical ratio.

A gear can also mesh a rack, thereby producing rotation instead of translation.

Pinion is smaller than a gear.

Technically bevel gear is the same as Herringbone gear.

Only nonferrous alloys, cast irons and powder-metallurgy are used in the manufacture of gears.

All gears can be shaped, broached, cast, and in the case of plastic gears, injection molded.

A quench press is used for large gears that are prone to warp.

Statement |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

T |

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

Task 5. Discuss with your partner:

T he new information you have got from the text.

Your own experience in using gears.

This is how we express our opinion in English. Study this table.

HOW TO EXPRESS OPINION: I think (that)… I consider (that)… I believe (that)… In my opinion … From my point of view … To my mind … As I see it … It seems to me … As for me … I guess … |

T ask 6. Listen to the description of gears and try to describe the main principle of gearing process. Give your own example of using gears.

Task 7. Answer the following questions based on the listening from Ex.6:

What is a gear?

What types of gear can you name?

How can two gears contact with each other?

The number of gear rotations is different, isn't it?

Smaller gears rotate slower than bigger gears, don't they?

What is mechanical advantage?

How can gears help to bypass the ship through a dam?

Task 8. Fill in the table. Name the types of gears and describe the main principle of their operation. Use the words from the box.

bevel gear double-helix gear spur gear ring spur worm gear helical gear helical rack face gear hypoid (spiral bevel) gear pinion rack

Name |

Definition |

Name |

Definition |

1) ____________ |

|

|

|

2)____________ |

|

|

|

3) __________ |

|

|

|

4)___________ |

|

|

|

|

|

|

|

Task 9. What measuring instruments do you know? List as many as you can. Compare your list with those of your groupmates.

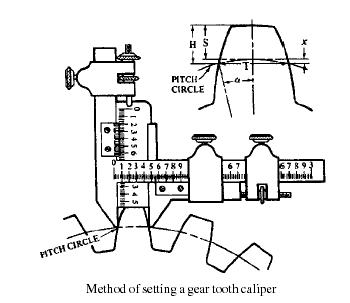

T ask

10. Try to describe the process in the picture. The following words

and word-combinations may help you:

ask

10. Try to describe the process in the picture. The following words

and word-combinations may help you:

the vertical/horizontal scale, to rest upon the top of the tooth, caliper, geared-wheel, as shown, to jaw, to determine, pitch circle, measurement, chordal thickness and addendum.

Task 11. Cross out the word that does not correspond to the other words in the line.

spur, bevel, line, helical;

depth, death, height, distance;

circle, circumference, round, scale;

movement, translation, rotation, oscillation;

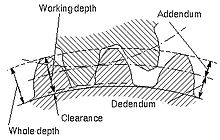

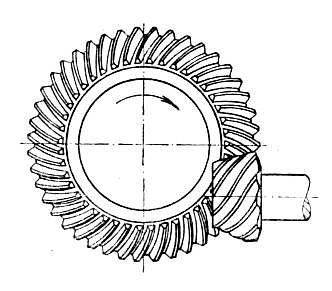

Task 12. Look at the picture. Try to give the definition to all gear parts.

W

orking

depth –

orking

depth –

Whole depth –

Clearance –

Dedendum –

Addendum –

Task 13. Fill in the gaps with proper words from the box. Use each word only once:

6)

________

6)

________

7)

________

7)

________

8)

________

8)

________

9)

________

9)

________ 5)

____________

5)

____________ 10)_______

10)_______