- •Передмова

- •Contents

- •Unit 1. Materials handling

- •Material Holding, Feeding and Metering

- •Hand chain hoists are portable lifting devices suspended from a hook and operated by _______ on a hand chain.

- •Unit 2. Gear and gearing (Part 1)

- •Gear and Gearing (part 1)

- •Unit 3. Geared systems and mechanisms (Part 2)

- •Gears and Gearing

- •Important, stock, reduced, figures, to be left,

- •Getting into shape: some basics

- •Unit 4. Metal-removal processes and machine tools

- •Material Removal Processes

- •Manufacturing techniques evaluation: cutting operations

- •Unit 5. Motion control systems overview

- •Motion Control System

- •Installation, shaft, servomotor, smooth, force, unit accumulate

- •Unit 6. Tool wear and sharpening

- •Tool wear

- •Unit 7. Bearings

- •Bearings. Components and specifications

- •Fig.1 Radial contact bearing terminology.

- •Principal standard bearing types

- •Unit 8. Mechanical elements (Part 1)

- •Machine Elements: Keys and Pins

- •Unit 9. Mechanical elements (Part 2)

- •Mechanical Elements: Rivets, Belts and Pulleys.

- •Write a list of all fasteners that you know. Compare it with the one of your groupmate.

- •Give the definition to the following terms and make sentences of your own with each of them:

- •Imagine that you are a young crazy inventor and someone presented you a large sum of money. In what field of science would you invest them or what would you do?

- •Unit 10. Mechanical failure modes

- •Mechanical Failure Modes

- •References:

- •How to make a presentation

- •Key phrases for preparing presentation

- •Why is writing an essay

- •Technical translation

- •Methods and Practices

- •Reading techniques

- •Skimming

- •Scanning

- •Using Context

- •Writing techniques

- •The Introduction

- •The body Paragraphs

- •The Conclusion

- •Irregular verbs

Unit 2. Gear and gearing (Part 1)

Task 1. What is the role of gears in modern world? What types of gear can you name?

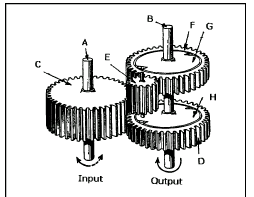

Task 2. Label the gear components on the diagram below. Use the words in the box.

idler, spur gear, output shaft, input shaft, free-wheel disk |

|

T ask 3. Watch the video and try to explain the main principles of a system of gears. Discuss this process with your groupmates.

Task 4. Read and translate the text.

Gear and Gearing (part 1)

External spur gears are cylindrical gears with straight teeth cut parallel to the axes. Gears transmit drive between parallel shafts. Tooth loads produce no axial thrust. Excellent at moderate speeds but tend to be noisy at high speeds. Shafts rotate in opposite directions.

Internal spur gears provide compact drive arrangements for transmitting motion between parallel shafts rotating in the same direction.

Helical gears are cylindrical gears with teeth cut at an angle to the axes. Provides drive between shafts rotating in opposite directions, with superior load carrying capacity and quietness than spur gears. Tooth loads produce axial thrust. Crossed helical gears are helical gears that mesh together on non-parallel axes. Straight bevel gears have teeth that are radial toward the apex and are of conical form. Designed to operate on intersecting axes, bevel gears are used to connect two shafts on intersecting axes. The angle between the shafts equals the angle between the two axes of the meshing teeth. End thrust developed under load tends to separate the gears.

Spiral bevel gears have curved oblique teeth that contact each other smoothly and gradually from one end of a tooth to the other. Meshing is similar to that of straight bevel gears but is smoother and quieter in use. Left hand spiral teeth incline away from the axis in an anti-clockwise direction looking on small end of pinion or face of the gear; right-hand teeth incline away from axis in clockwise direction. The hand of spiral of the pinion is always opposite to that of the gear and is used to identify the hand of the gear pair and to connect two shafts on intersecting axes as with straight bevel gears. The spiral angle does not affect the smoothness and quietness of operation or the efficiency but does affect the direction of the thrust loads created. A left-hand spiral pinion driving clockwise when viewed from the large end of the pinion creates an axial thrust that tends to move the pinion out of mesh.

Zero bevel gears have curved teeth lying in the same general direction as straight bevel teeth but should be considered to be spiral bevel gears with zero spiral angles.

Hypoid bevel gears are a cross between spiral bevel gears and worm gears. The axes of hypoid bevel gears are non-intersecting and non-parallel. The distance between the axes is called the offset. The offset permits higher ratios of reduction than is practicable with other bevel gears. Hypoid bevel gears have curved oblique teeth on which contact begins gradually and continues smoothly from one end of the tooth to the other.

Worm gears are used to transmit motion between shafts at right angles, that do not lie in a common plane and sometimes to connect shafts at other angles. Worm gears have line tooth contact and are used for power transmission, but the higher the ratio the lower the efficiency.

If a gear tooth of the involute curvature acts against the involute tooth of a mating gear while rotating at a uniform rate, the angular motion of the driven gear will also be uniform, even though the center-to-center distance is varied.

The relative rate of motion between driving and driven gears having involute tooth curves is established by the diameters of their base circles.

Contact between intermeshing involute teeth on a driving and driven gear is along a straight line that is tangent to the two base circles of these gears. This is the line of action.

The point where the line of action intersects the common center-line of the mating involute gears, establishes the radii of the pitch circles of these gears; hence true pitch circle diameters are affected by a change in the center distance. (Pitch diameters obtained by dividing the number of teeth by the diametric pitch apply when the center distance equals the total number of teeth on both gears divided by twice the diametric pitch.)

The pitch diameters of mating involute gears are directly proportional to the diameters of their respective base circles; thus, if the base circles of one mating gear is three times as large as the other, the pitch circle diameters will be in the same ratio.

The angle between the line of action and a line perpendicular to the common center-line of the mating gears, is the pressure angle; hence the pressure angle is affected by any change in the center distance. When an involute curve acts against a straight line (as in the case of an involute pinion acting against straight-sided rack teeth), the straight line is tangent to the involute and perpendicular to its line of action. The pressure angle, in the case of the involute pinion acting against straight-sided rack teeth, is the angle between the line of action and the line of the rack's motion. If the involute pinion rotates at a uniform rate, movement of the rack will also be uniform.

Task 5. The definitions of the terms are given. Guess these terms and put down these words into the table.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Task 6. Match the words from column A with column B. Make word combinations and translate them into Ukrainian:

-

A

B

contact __

pitch

contact __

ratio

diametral __

advance

equivalent pitch __

radius

face __

tooth

fillet __

overlap

flank of __

radius

helical __

stress

Task 7. Match the first part of the definition of the following terms (1-6) with the second one (a-f).

|

|

|

|

|

|

|

|

|

|

|

|

Task 8. Define whether the following statements are true or false. Correct the false ones.

Gear tooth system standards are established by specifying the tooth mass of the basic rack.

The diametric pitch system is applied to most of the gearing produced in the United States.

If gear teeth are larger than about one diametric pitch, it is common practice to use the triangular pitch system.

The circular pitch system is also applied to cast gearing and it is commonly used in connection with the design and manufacture of worm gearing.

The diametral pitch system is arranged to provide a series of different tooth sizes, the principle being similar to the standardization of screw thread pitches.

Inasmuch as there must be a whole number of teeth on each gear, the increase in pitch diameter per tooth varies according to the pitch.

Statement |

1 |

2 |

3 |

4 |

5 |

6 |

T |

|

|

|

|

|

|

F |

|

|

|

|

|

|

Task 9. Complete the following sentences using the wordlist below. Use each word only once.

thickness distance circular determined ratio tooth diameter arc pitch |

1. When it is necessary to use a pair of gears of given 1) ____ at a specified center distance, it may be found that no gears of standard diametric pitch will satisfy the center 2) ___ requirement. 2. If the outside 3) ___ of a gear is reduced, as is frequently done to maintain the standard center distance when the outside diameter of the mating pinion is increased, the 4) ___ thickness of the gear teeth at the standard pitch diameter will be reduced. 3. The tooth thickness on the pitch circle can be 5) __ very accurately by means of measurement over wires which are located in 6) ___ spaces that are diametrically opposite or as nearly diametrically opposite as possible. 4. Where measurement over wires is not feasible, the circular or 7) ___ tooth thickness can be used in determining the chordal 8) ____ which is the dimension measured with a gear tooth caliper. 5. When the outside diameter of a small pinion is not standard but is enlarged to avoid undercut and to improve tooth action, the teeth are located farther out radially relative to the standard 9) ___ diameter and consequently the circular tooth thickness at the standard pitch diameter is increased.

Task 10. Translate the following sentences into Ukrainian.

1) Gears designed with a hole should have the hole large enough that the blank can be adequately supported during machining of the teeth and yet not so large as to cause distortion. 2) Face widths should be wide enough, in proportion to outside diameters, to avoid springing and to permit obtaining flatness in important surfaces. 3) Short bore lengths should be avoided wherever possible. 4) Where gear blanks with hubs are to be designed, attention should be given to the wall sections of the hubs. 5) Too thin a section will not permit proper clamping of the blank during machining operations and may also affect proper mounting of the gear.

Task 11. Complete the following statements from column A with the corresponding terminations from column B.

A |

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Task 12. Fill in the gaps in the following text. Choose one of the offered variants.

light oil lubricant gears frictional helix backlash |

Other important considerations are speed and space for 1) … film. Slow-moving 2) …, in general, require the least backlash. Fast-moving fine-pitch gears are usually lubricated with relatively 3) …, but if there is insufficient clearance for an oil film, and particularly if oil trapped at the root of the teeth cannot escape, heat and excessive tooth loading will occur. The heat may result from oil churning or from 4) … losses between the teeth, at bearings or oil seals, or from external causes. The higher the 5) … angle or spiral angle, the more transverse backlash is required for a given normal backlash. The transverse 6) … is equal to the normal backlash divided by the cosine of the helix angle.

Task 13. Match the first part of a sentence (1-5) with the second one (a-e).

Hypoid gears are offset and in effect, are spiral …

The visualization of hypoid gears is based on an …

The staggered axes result in meshing conditions that are …

With spiral gears, great differences in sliding motion arise over various portions of …

Surface pressures are thus reduced so that there is less …

… imaginary flat gear which is a substitute for the theoretically correct helical surface.

… beneficial to the strength and running properties of the gear teeth.

… the tooth surface, creating vibration and noise.

… gears whose axes do not intersect but are staggered by an amount decided by the application.

… wear and quieter operation.

Task 14. Match the words from column A with column B to make up word combinations and translate them into Ukrainian:

A |

B |

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

COMMON ELEMENTS OF A REPORT

T Introduction includes a formal thesis statement purpose and clearly states the Background (subheading) and Objectives (subheading). Leads the reader to content (what is being studied). Answer who? What? Where? Why? When? How? Background, subheading: Why is the study being conducted? What is the importance or significance of the project? Keep this section as brief as possible. Full Schematic. A schematic is a diagram that is useful in helping the audience to see what the product should look like. Schematics should be descriptively labeled with figure number, title, and brief description, or caption. It should provide the reader with items such as measurements, tables, cost, and a legend (if necessary). Include all parts needed to accomplish the project with cost and sources list. Solutions, paragraph form, longest section! Inevitably, the audience will run into roadblocks. Let the reader know what possible problems are and offer descriptions as to how to remedy or avoid problems. Evidence:What are the results of the investigation? Represent the findings. Usually a written/verbal representation of the information in the tables. |

|

|

Task 15. Write a short report (80-100 words) about the process shown in the picture below.

Task 16. Watch the video file “Planetary Gear System”. Write a short report (100-120 words) on how it works.