- •Global Strategy at General Motors

- •Introduction

- •Strategy and the Firm

- •Support Activities

- •The Role of Strategy

- •Profiting from Global Expansion

- •Transferring Core Competencies

- •Realizing Location Economies

- •Creating a Global Web

- •Some Caveats

- •Realizing Experience Curve Economies

- •Learning Effects

- •Strategic Significance

- •Pressures for Cost Reductions and Local Responsiveness

- •Figure 12.3

- •Pressures for Cost Reductions

- •Differences in Infrastructure and Traditional Practices

- •Differences in Distribution Channels

- •Host Government Demands

- •Implications

- •Strategic Choice

- •International Strategy

- •Figure 12.4

- •Multidomestic Strategy

- •Global Strategy

- •Transnational Strategy

- •Summary

- •Figure 12.6

- •Case Discussion Questions

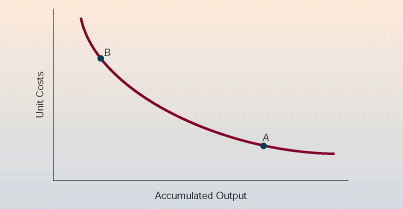

Realizing Experience Curve Economies

The experience curve refers to the systematic reductions in production costs that have been observed to occur over the life of a product.8 A number of studies have observed that a product's production costs decline by some characteristic each time accumulated output doubles. The relationship was first observed in the aircraft industry, where each time accumulated output of airframes was doubled, unit costs typically declined to 80 percent of their previous level.9 Thus, production cost for the fourth airframe would be 80 percent of production cost for the second airframe, the eighth airframe's production cost 80 percent of the fourth's, the sixteenth's 80 percent of the eighth's, and so on. Figure 12.2 illustrates this experience curve relationship between production costs and output. Two things explain this: learning effects and economies of scale.

Learning Effects

Learning effects refer to cost savings that come from learning by doing. Labor, for example, learns by repetition how to carry out a task, such as assembling airframes, most efficiently. Labor productivity increases over time as individuals learn the most efficient ways to perform particular tasks. Equally important, in new production facilities, management typically learns how to manage the new operation more efficiently over time. Hence, production costs eventually decline due to increasing labor productivity and management efficiency.

Learning effects tend to be more significant when a technologically complex task is repeated because there is more that can be learned about the task. Thus, learning effects will be more significant in an assembly process involving 1,000 complex steps than in one of only 100 simple steps. No matter how complex the task, however, learning effects typically die out after a time. It has been suggested that they are important only during the start-up period of a new process and that they cease after

Figure 12.2

The Experience Curve

two or three years.10 Any decline in the experience curve after such a point is due to economies of scale.

Economies of Scale

The term economies of scale refers to the reductions in unit cost achieved by producing a large volume of a product. Economies of scale have a number of sources, one of the most important of which seems to be the ability to spread fixed costs over a large volume.11 Fixed costs are the costs required to set up a production facility, develop a new product, and the like, and they can be substantial. For example, establishing a new production line to manufacture semiconductor chips costs about $1 billion. According to one estimate, developing a new drug costs about $250 million and takes about 12 years.12 The only way to recoup such high fixed costs is to sell the product worldwide, which reduces unit costs by spreading them over a larger volume. Also, the more rapidly that cumulative sales volume is built up, the more rapidly fixed costs can be amortized, and the more rapidly unit costs fall.

Another source of scale economies arises from the ability of large firms to employ increasingly specialized equipment or personnel. This theory goes back over 200 years to Adam Smith, who argued that the division of labor is limited by the extent of the market. In simple terms, this means that as a firm's output expands, it is better able to make full use of specialized equipment, and has the output required to justify the hiring of specialized personnel. Consider a metal stamping machine that is used in the production of automobile body parts. The machine can be purchased in a customized form, which is optimized for the production of a particular type of body part, or a general purpose form, which will produce any kind of body part. The general form is less efficient and costs more to purchase than the customized form, but it is more flexible. Since these machines cost millions of dollars each, they have to be used continually to recoup a return on their costs. Fully utilized, a machine can turn out about 200,000 units a year. If an automobile company sells only 100,000 cars a year, it will not be worthwhile purchasing the specialized equipment, and it will have to purchase general purpose machines. This will give it a higher cost structure than a firm that sells 200,000 cars per year and for which it is economical to purchase a specialized stamping machine. Thus, because a firm with a large output can more fully utilize specialized equipment (and personnel), it should have a lower unit cost than a firm that must use generalized equipment.