Basic_Electrical_Engineering_4th_edition

.pdf

DC MACHINES |

269 |

Armature copper losszat any load current Ia2 Ra, v

Field copper loss = -

Rr,

Total loss at load = Mechanical andironlosses+Armaturecopperloss+ FieldCopperloss + Stray Loss

Swinburnetestcanthusbeutilisedtoobtainefficiencyofthe machine at differentloadings. However, the test does notprovide anyinformationregardingthe temperaturerise ofthe windings ofthe machine.

Example 6.11. Swinburne test gave the following results on a de shunt motor:

Supply voltage 500 V, no load current 5A, Armature resistance 0.5.Qand Field resistance 250 .D. Determine the efficiency ofthe machine (i) as a generator delivering 100A at 500 V(ii) as a motor having a line current of 100 A at 500 V Neglect temperature rise during operation. Assume stray losses at 1 % of output.

Solution. Input at no load

500 x 5 = 2500 watts

Field current |

|

I = |

500 |

= 2 A |

|

|

|

|

|

|

250 |

|

|

|

|

Hence armature current |

5 |

- 2I= 3 A= 22 x 250 = 1000 watts |

|||||

Field copper loss |

|

||||||

Armaturecopper loss |

|

|

= 32 x 0.5 = 4.5 watts |

||||

Mechanical and iron loss |

|

|

|

2500 - 1000 - 4.5 |

|||

|

|

|

= 1495.5 watts |

||||

(z) Working as a generator |

|

= |

500 x 100 |

|

|

||

Output power |

|

|

|

|

50,000 watts |

||

Armature current |

|

100 + 2 = 102 A |

|

|

|||

Armaturecopperloss |

|

|

= 1022 x 0.5 = 5202 watt |

||||

|

|

= |

1 |

|

= |

||

|

Stray loss = |

x 50,000 = 500 watts |

|||||

|

500 x 100 = |

-- |

|

|

|

||

|

|

|

|

100 |

|

|

|

Total losses = 5202 + 1000 + 1495.5 + 500 |

|||||||

|

|

|

= 8197.5 watts |

||||

|

|

. . |

|

50000 |

|

|

|

Hence efficiency = 58197.5 = 0 |

.86 or 860Yo Ans. |

||||||

(iz) Working as a motor |

|

|

|

|

|

|

|

Input to the motor |

|

|

|

50,000 watts |

|||

Armature current |

|

100 - 2 = 98 A |

|

|

|

||

Armaturecopper loss |

|

|

= 982 x 0.5 = 4802 watts |

||||

Output = 50,000 - 4802 - 1000 - 1495.5 = 42702.5 watts

Stray loss = 427 watts

270 |

|

ELECTRICAL ENGINEERING |

Hence net output = 42702.5 |

- 427 = 42275.5 watts |

|

. . |

42275.5 |

|

Hence efficiency = |

50,000 |

x 100 = 84.55% Ans. |

Example 6.12. A 100 KW belt driven shunt generator running at 300 rpm on 220 V bus bars continues to run as a motor when the belt breaks then taking 10 KW. Determine its speed. Assume armature resistance 0.025 D, field resistance 60 Q contact drop under each brush 1 V. Ignore armature reaction.

Solution. Current taken bv the motor lO,OOO220

Initially current delivered bythe generator 455 A Hence the induced emf 220 + 455 x 0.025 = 231.375

The back emfwhile motoring 220 - 45.5 x 0.025 = 218.87 V

Add 2 volts contact drop in case ofgenerator and subtract 2 volts in case ofmotor, we have |

||||||

Total induced emffor generator 233.375 and for the motor back emf216.87 |

||||||

Hence the speed under motoring• |

condition |

|

|

|||

216·87 |

x 300 |

= |

279 ·p |

m |

Ans. |

|

233.375 |

|

|

r |

|

||

Example 6.13. A series generator, having an external characteristic which is a straight line through zero to 50 V at 200 A, is connected as a booster between a station bus bar and a feeder of 0.3 Q resistance. Determine the voltage between the far end of the feeder and the bus bar at a current of (a) 1 60 A (b) 50 A.

Solution. (a) Since the generator characteristic is a straight line passing through the origin, at 160 A the bus bar voltage willbe

20050 x 160 = 40 volts

and the drop in the feeder due to the flow of 160 Ais 160 x 0.3 = 48 volts

and hence the difference ofvolts between the bus bar and the far end ofthe feeder is 48 - 40 = 8 volts Ans.

(b) Similarly for 50 A, the bus bar voltage is

50

200

andthe drop inthe feeder due to 50A current flowis 50 x 0.3 = 15 volt

and hence the difference in voltage is

15 - 12.5 = 2.5 V Ans.

Example 6.14. A long shunt compound generator delivers a load current of 50 A at 500 V and has armature, series field and shunt field resistances of 0.05 !1, 0.03 Q and 250 Q respec tively. Determine the induced emf and the armature current. Allow 1 volt per brush for contact drop.

DC MACHINES |

|

|

|

|

|

|

271 |

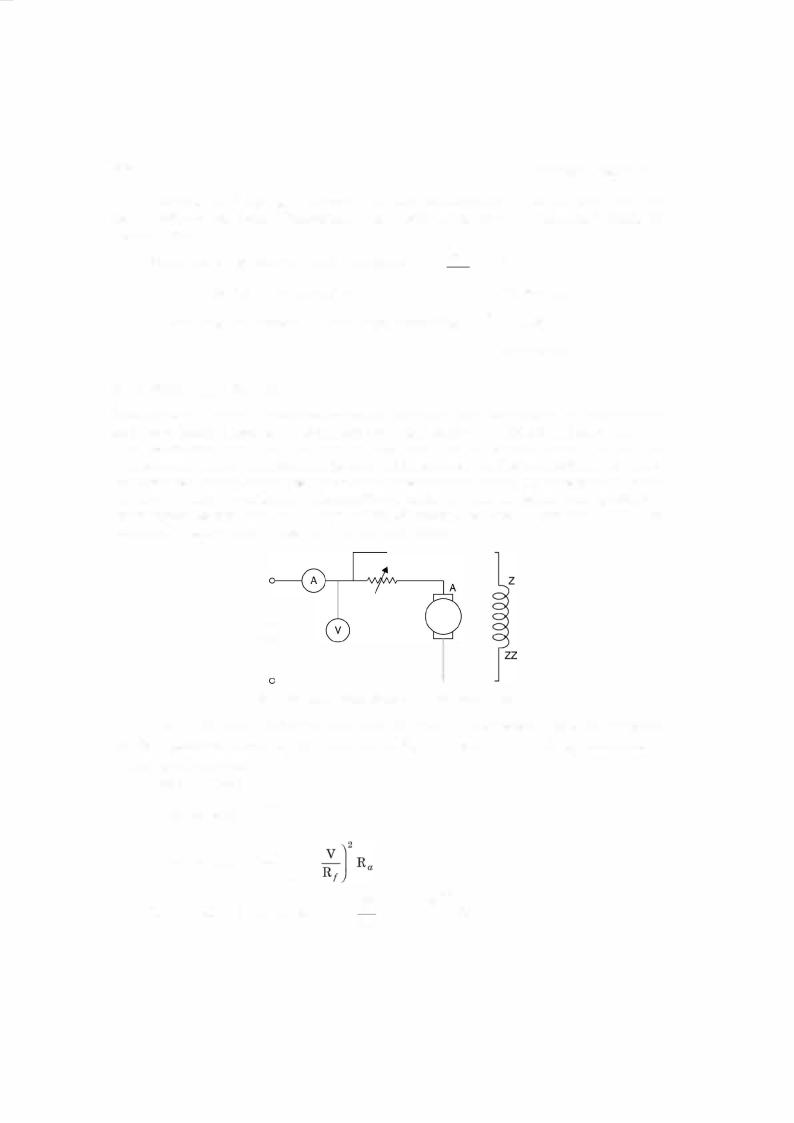

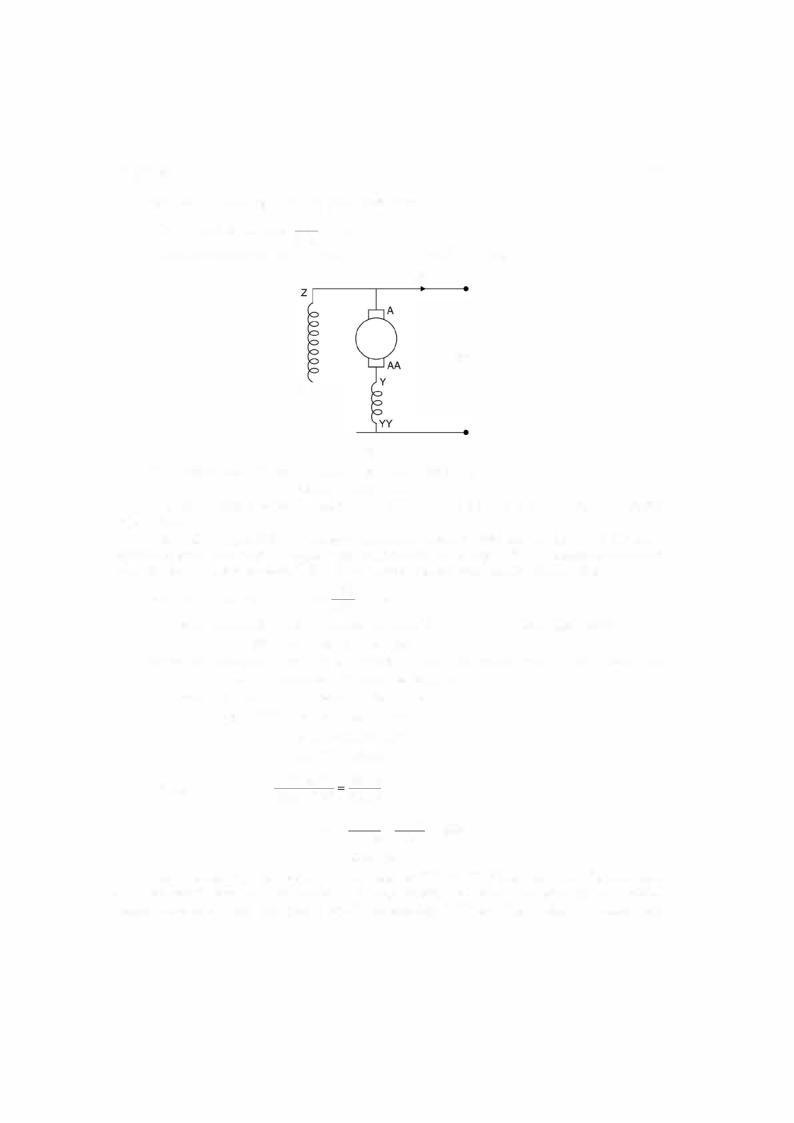

Solution. The long shunt figure is given here |

|

|

|||||

The shunt field current |

5oo |

= 2 A |

|

|

|

|

|

Hence armature current |

250 |

= I + |

]sh |

= 50 |

+ 2 = 52 A |

|

|

Ia |

Ans |

. |

|||||

L |

|

|

|

||||

|

|

|

|

|

50 A |

|

|

500 v

zz

|

|

|

|

|

|

Fig. E6.14 |

|

|

|

|

|

|

The drop in the armature and the series field resistance |

|

|

|

|

||||||||

|

52(0.05 |

|

|

0.03) = 4.16 |

|

|

|

|

|

|||

The brush drop 2 volts. Hence the e.m.f. induced is 500 + 2 + 4.16 = |

|

|

||||||||||

volts. Ans. |

|

|

|

+ |

|

|

|

|

|

506.16 '.:::'506..2 |

||

Example 6.15. A 250 Vshunt motor on no load runs at 1000 rpm and takes 5A. The total |

||||||||||||

armature and shunt field resistances are respectively 0.2 .Q and 250 |

|

Determine the speed |

||||||||||

when loaded taking a current of 50A, if armature reaction weahens the field by |

|

|||||||||||

Solution. The field current is |

|

250 = 1 A |

|

|

.Q. |

|

|

3%. |

||||

|

|

250 |

|

|

|

|

|

|||||

Under no load condition the armature current is 5 - 1 = 4 A. Hence back emfis |

||||||||||||

|

250 - 4 x 0.2 |

|

|

|

249.2 volts |

|

|

|

|

|

||

Since the armature current is 4 A which is very small as compared to 50 A as far as |

||||||||||||

armature reaction effect inconcerned, hence we neglect the effect. |

|

|

|

|

||||||||

|

|

|

= |

|

|

|

|

|

|

|

|

|

The back emfwhen 50 A is drawn by the motor |

|

|

|

|

|

|||||||

Now |

250 - (50 - 1) x 0.2 = 240.2 volts |

|

|

|

|

|

||||||

249.2 =Kqi x 1000 |

|

|

|

|

|

|||||||

|

240.2 |

|

= |

|

0.97 KN |

|

|

|

|

|

|

|

Hence |

0.97 KNcp |

|

|

240.2 |

|

|

|

|

|

|

||

Kcp x 1000 |

|

249.2 |

|

|

|

|

|

|

||||

or |

N= |

|

240.2 x |

1000 |

- 993_7 |

|

|

|

|

|||

|

|

|

|

|

|

249.2 |

0.97 |

|

|

|

|

|

'.:::'994rpm. .

Example 6.16. A shunt generator delivers 50 KWat 250 Vand 400 rpm. The armature and field resistances are 0.02 .Q and 50 .Q respectively. Determine the speed of the machine running as a shunt motor and taking 50KWinput at 250 V Allow 1 Vper brush for contact drop.